- Simple Operation

- No Nightly Clean Up

- Consistent & Accurate Application

- Economical

- Complete Mechanical Operation

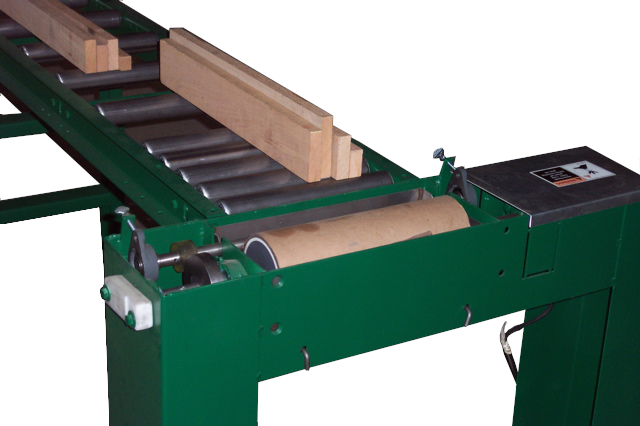

The Plate Spreader is ideal for use with small to medium (6 section to 20 section) sized Clamp Carriers. It is a simple, rugged design, yet it mechanizes the glue application operation.

The glue spreader is built with an aluminum grid and stainless steel pan. The grid is stationary and immersed in the reservoir of glue. The glue pan is spring loaded upward. The operator presses the foot treadle to the floor, lowering the pan of glue and exposing the grid. The stock to be glued is placed on the grid and a uniform coat of adhesive is transferred to the stock.

The treadle is released, and the pan rises and once again immerses the grid. The Plate Spreader is 4’ long but when the treadle is depressed and the pan lowered, the grid is completely exposed so longer stock can be step coated.

In the evening, no clean up is required. Simply use the anodizing bottle that comes with the machine to apply a light film of water over the glue. Then, place the cover over the glue pan to keep the glue moist. There is no clean up!