Rip Systems

Advantages of a Cameron Machine:

- Multiple Infeed and Saw Models to fit your Production Needs

- Auto Skewing and Movable Blades for the Industry's Best Yield

- Cutting Edge and Powerful Software

- Industry Leading Service and Support

#411A- Skew Rip System

The Industry’s Best Value!! Designed for Small and Medium Shops looking for High Efficiency and Throughput

The Cameron Skew System will cut up to (5) Boards per minute, maximizing the yield of raw materials, and the efficiency of the work cell

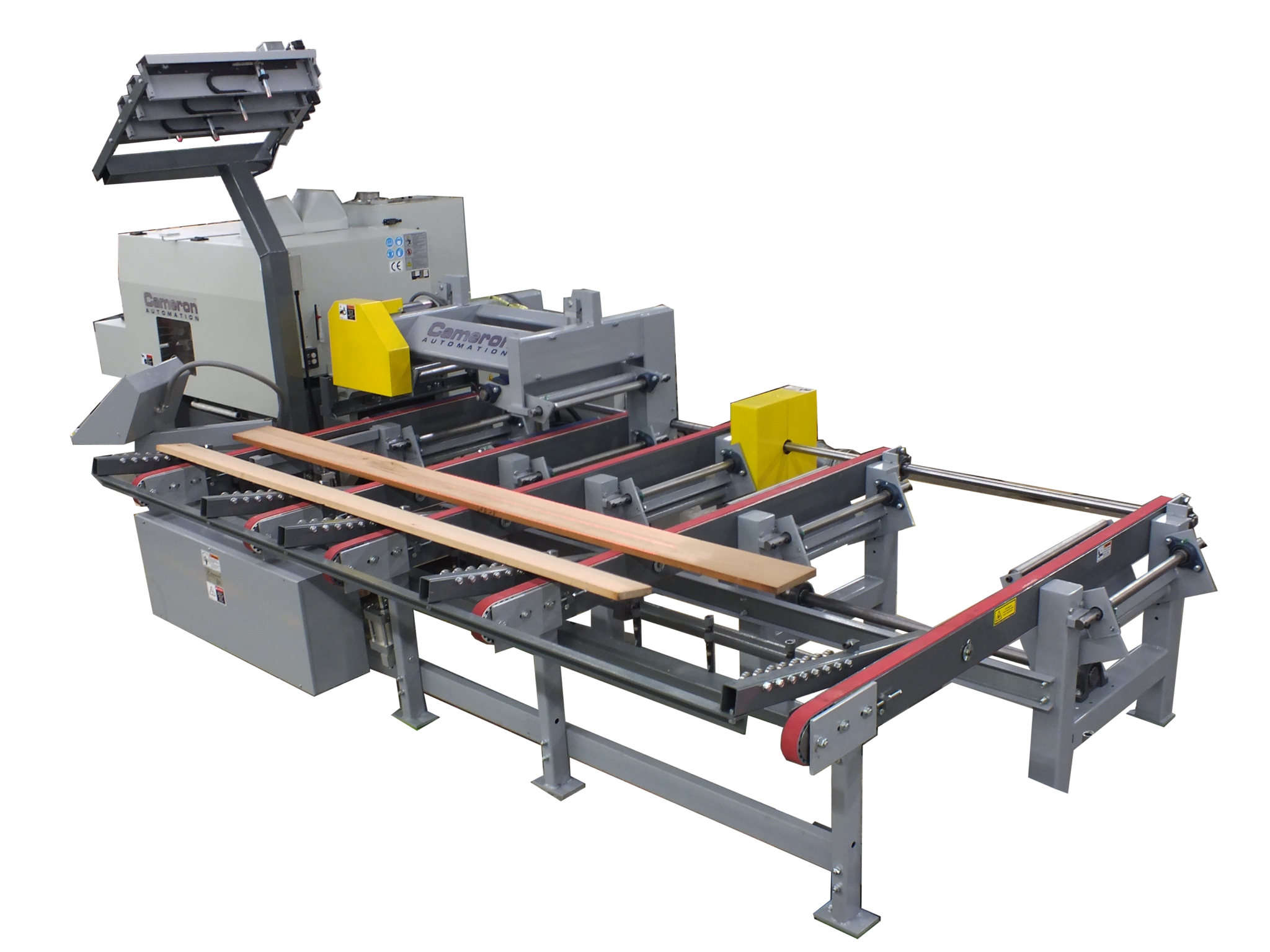

#415A- Quick Rip System

The Industry’s only Fenceless Design for Feeding Boards into a Rip Saw. Designed for the Medium and Large Shops looking for maximum yield and throughput

The Quick Rip System will cut up to (10) Boards per minute with the highest possible yield on the Market

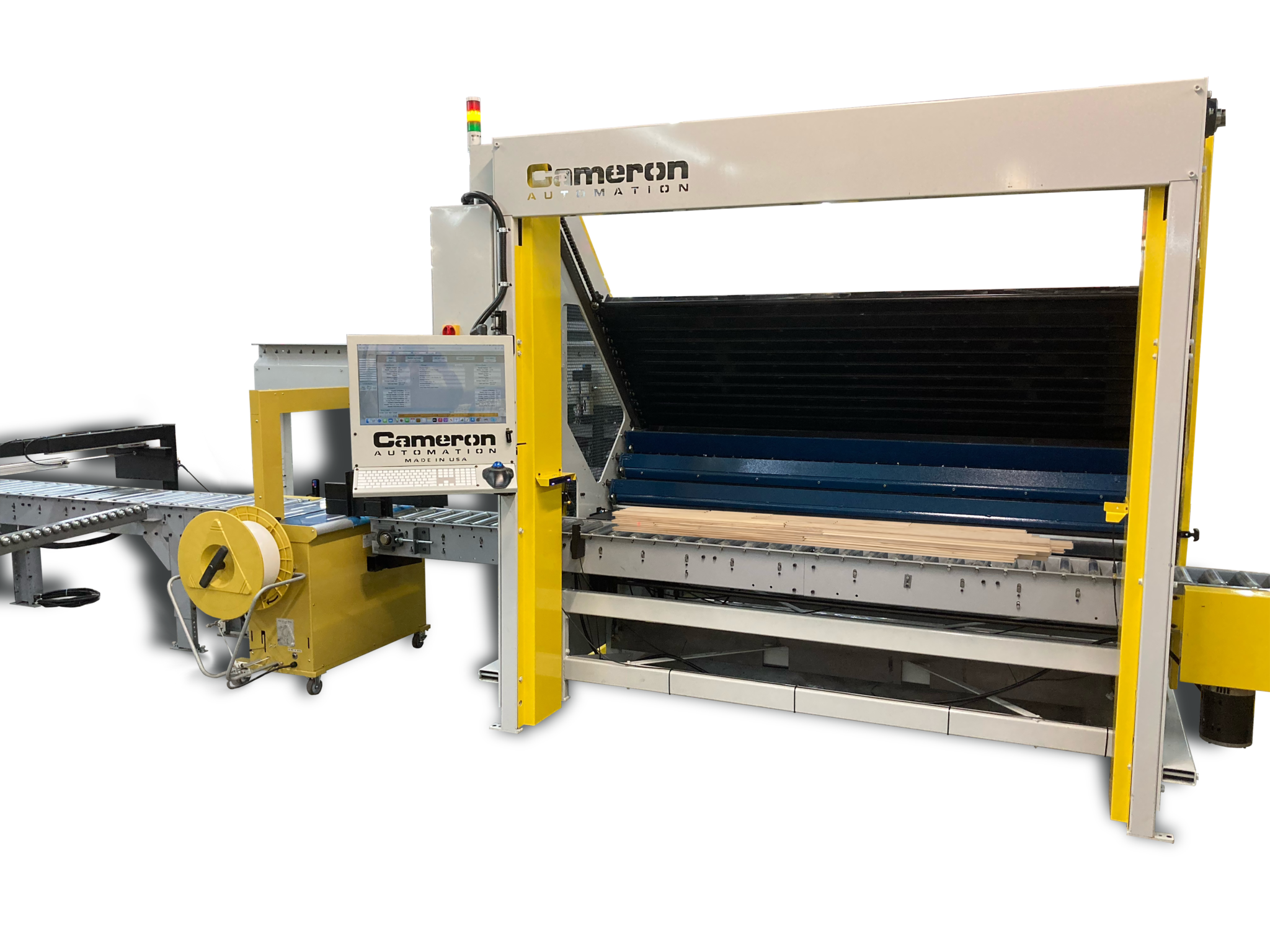

#415A-AOR – The Automated Opti-Rip

Utilize the Industry Leading Quick Rip Technology in a Large, full production lumber line

Cameron Automation’s Largest Infeed, capable of running 10+ Boards per minute, for the High Production Lumber Mills and Large Woodworking Factories

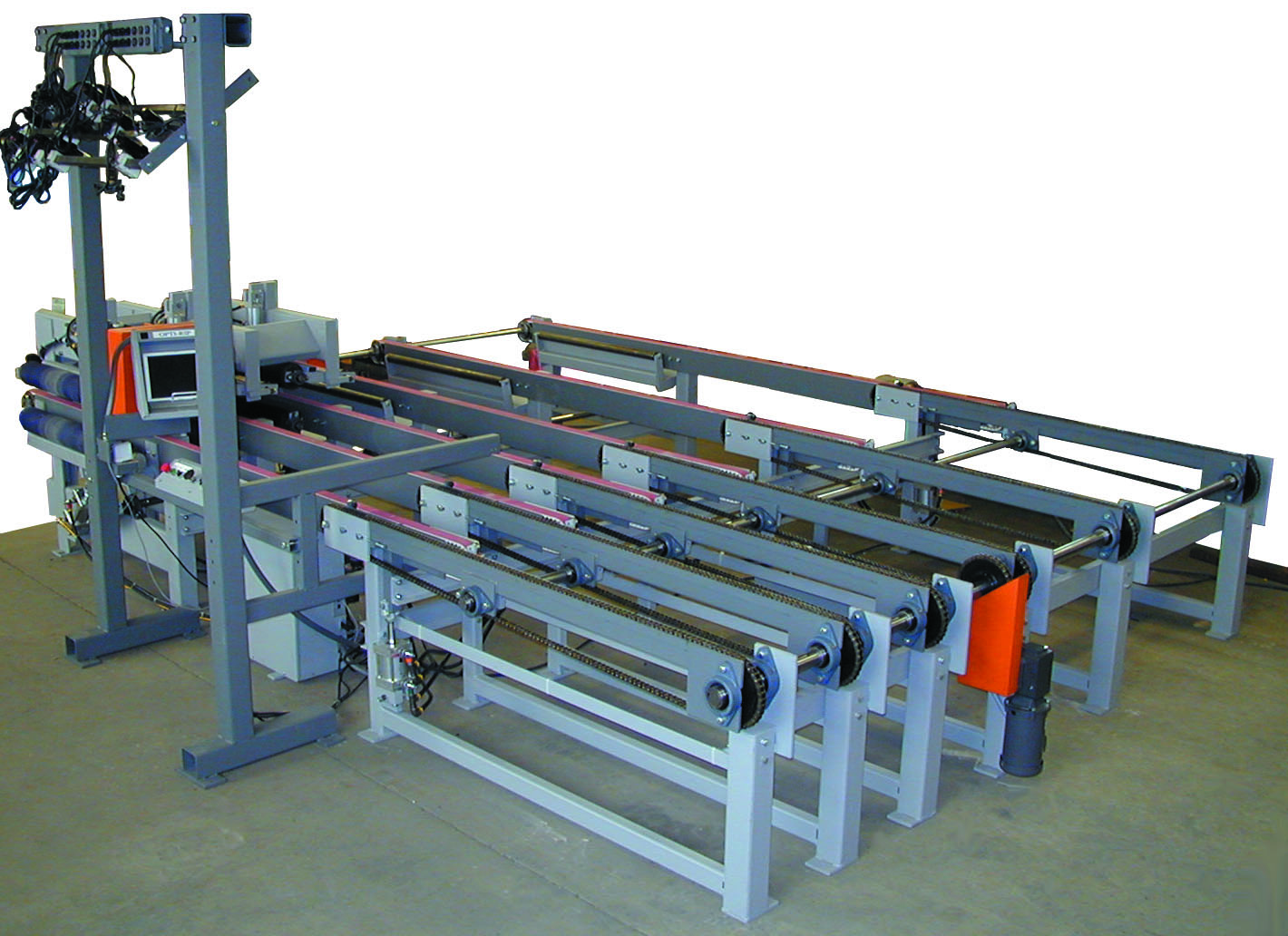

#412A- Rip One System

A Complete Lumber Scanning, Optimization, and Gang Ripping Work Cell designed for Medium and Small Shops

Scan and rip up to (10) boards per minute. The Rip One will increase your yield and make better decisions with each and every board

#413- Cameron Moving Blade Rip Saws

Cameron Rip Saws are the best Value in the Industry. Heavy Construction Coupled with Cameron Software and Support create a very Industrial package for a Competitive Price

Cameron Rip Saws are available in (3) different setups: 1). 12″ wide arbor with (2) moving blades, 2). 18″ wide arbor with (3) moving blades, and 3). 24″ wide arbor with (4) Moving Blades. Fixed pockets are possible on all Cameron Saw models as well to maximize material yield and work cell efficiency.