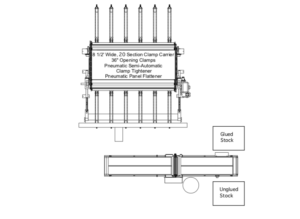

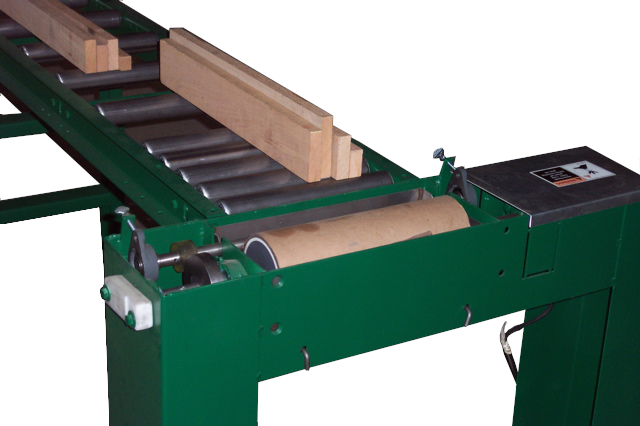

The #80U Swing Style Clamp Carrier is a reliable and versatile clamping machine. This rugged, heavy duty design will handle any job in your custom shop.

Features:

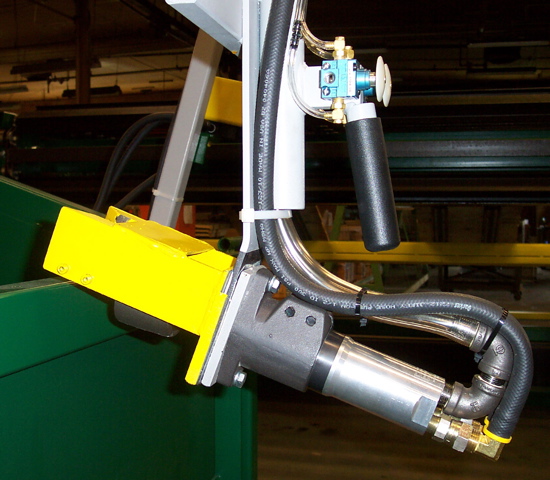

- Push Button Flattening

- Push Button Tightening & Loosening

- Joystick’ Power Rotation with an Air Motor Drive

- Heavy Duty Frame with Steel Base

- Frame Widths Ranging in Size from 8.5 Ft – 16.5 Ft Wide

- Taylor Clamp Arms with a range in size from 32″ – 44″

- 2-1/2″ (65mm) & 3-1/2” (90mm) High Clamp Jaws

- Up to 6” (150mm) Thick Gluing with Optional Rocker Plate Jaw Extensions

(Additional Details and Info Below)

Taylor Clamp Carriers are expandable and upgradeable. The number of sections can be increased at anytime to allow for more clamp time and cure time. When higher production is needed, the tightener & flattener system can be switched out and upgraded to a more automated and productive front end at any time. The clamp carrier frame and the clamp arms can all be reused, keeping the cost of the project lower.