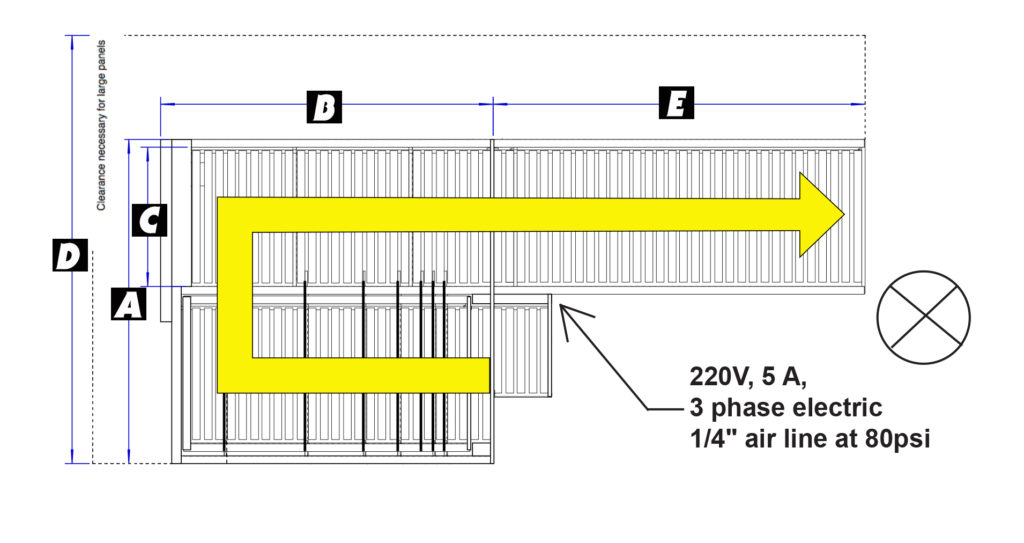

Features:

- (4) machine lengths return material up to 60″, 96″, 112″ long, or 132″ Long.

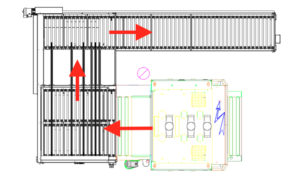

- Photo-eye triggers drop of receiving conveyor. A PLC adjusts the timing automatically based on conveyor speed

- Drop away receiving conveyor gently transfers parts to cross conveyor

- 12″, 24″, and 36″ Transfer sections between the catch and the return to create space for maintenance on the sander

- 24″ or 36″ Wide Rollers on return conveyors can handle up to 50″ wide material

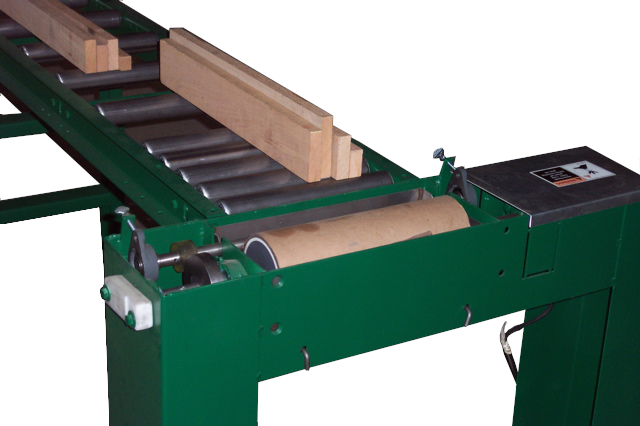

- All rollers are powered and individually clutched for long belt life

- Any Length Return (in one foot increments) composed of modular sections

- Roller Spacing 3″ center to center

- Any Length Return Section composed of modular sections

- 5″ Stroke Motorized height adjustment for movable bed Sander models

- Minimum material size 1″ x 6″

- Variable Speed AC drive matches conveyor feed rate to sander feed rate

The Taylor Return Conveyor for use with a wide belt sander has several special features. If necessary it can be equipped with An extra transfer section to create clearance for the width of the sander, Casters on all legs allow it to be rolled away from the side of the machine for belt changes or sander maintenance, and Powered height adjustment for movable bed sanders.

(Additional Details and Info Below)