Cameron Automation Products

- Development of High Tech Machinery

- Efficient and Productive Mechanical Designs

- Sophisticated and Powerful Software

- Increased Raw Material Utilization

- Industry Leading Customer Service by a Highly Trained Technicians

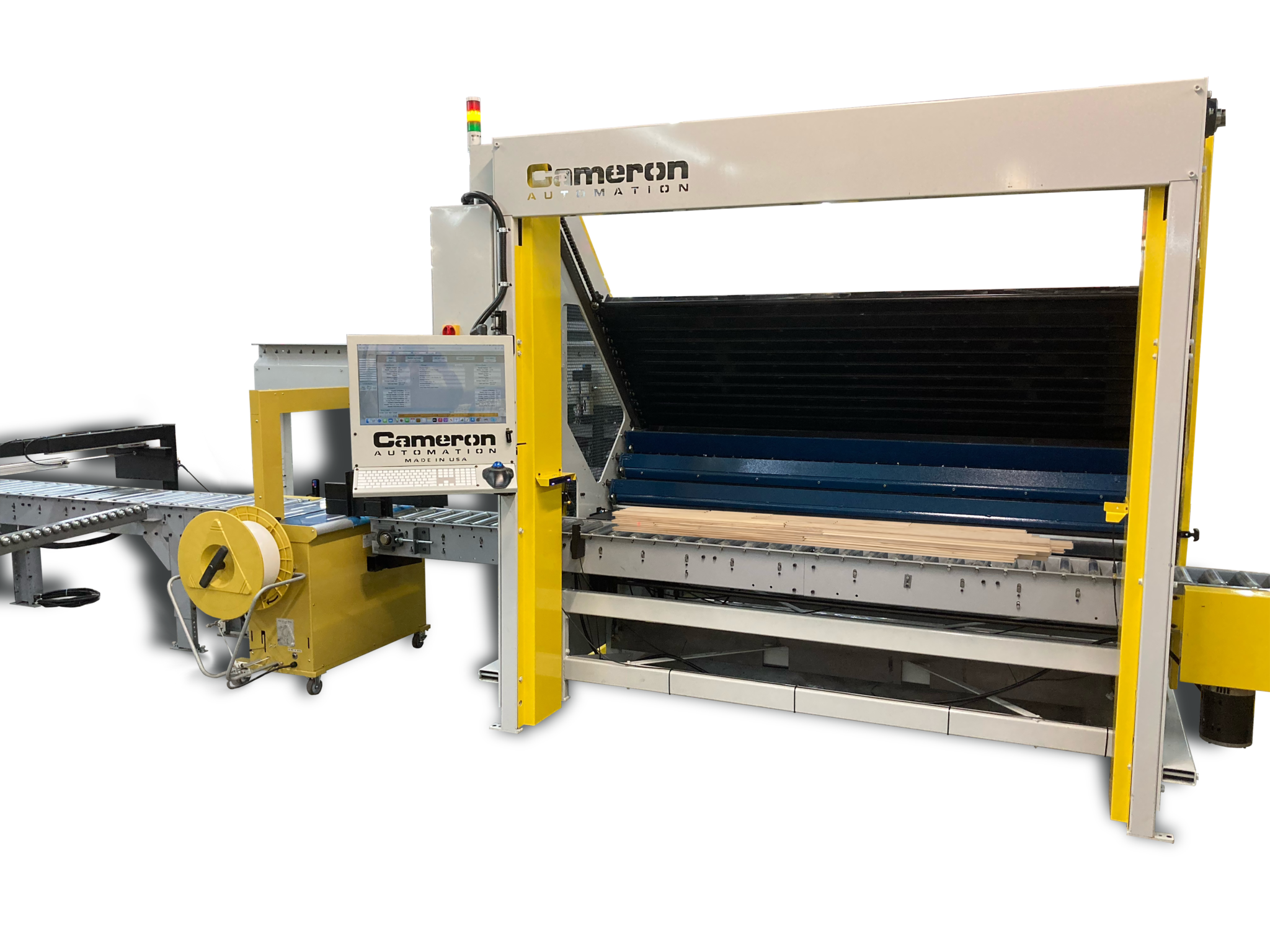

Flooring Systems

Cameron Automation has the technology to automate your flooring nesting, bundling and pack operation for both strip flooring and wide plank in both solid and engineered. Cameron Automation can also help with Out-Feed Roller Conveyors to convey, strap and stack your flooring bundles.

Click Below to learn more about Cameron’s Flooring Nesters and Out-Feed Roller Conveyor Systems.

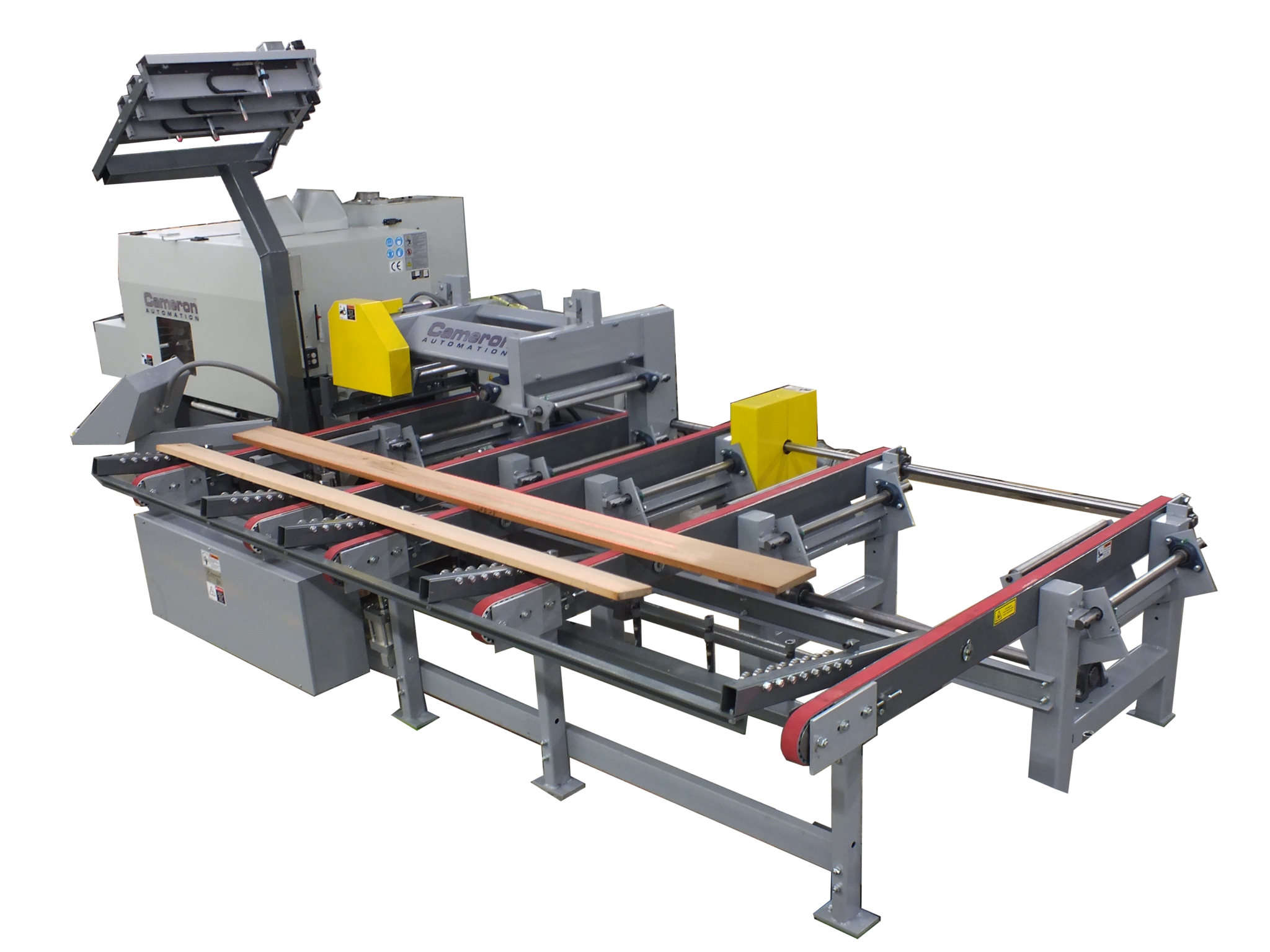

Rip Systems

Cameron Automation offers a versatile and efficient line up of Rip System Models. Industry leading technology and software are a staple among the models. Common features like Auto Skewing, multiple moving blades on the Rip Saw, and our powerful “Opti-Rip” Software create machinery packages that have the highest yield on the market. Customers who rip a pack each day, or more, should consider a Cameron Rip System for their shop.

Click Below to learn more about Cameron Rip Systems

Chop Optimization

A redesign of the tried and true #37A, the #611A Cameron Quick Chop is a high speed optimizing chop saw. Crayon marking for defects and highly accurate, the Quick Chop can defect and cut many different types of wood components to length. Coupled with full blown optimizing software, production tracking, multiple grades, and import capabilities, the Quick Chop can be used to everything from simple cut lists to much more complicated kitchen at a time style of lists.

Click Below to learn more about the Cameron Quick Chop

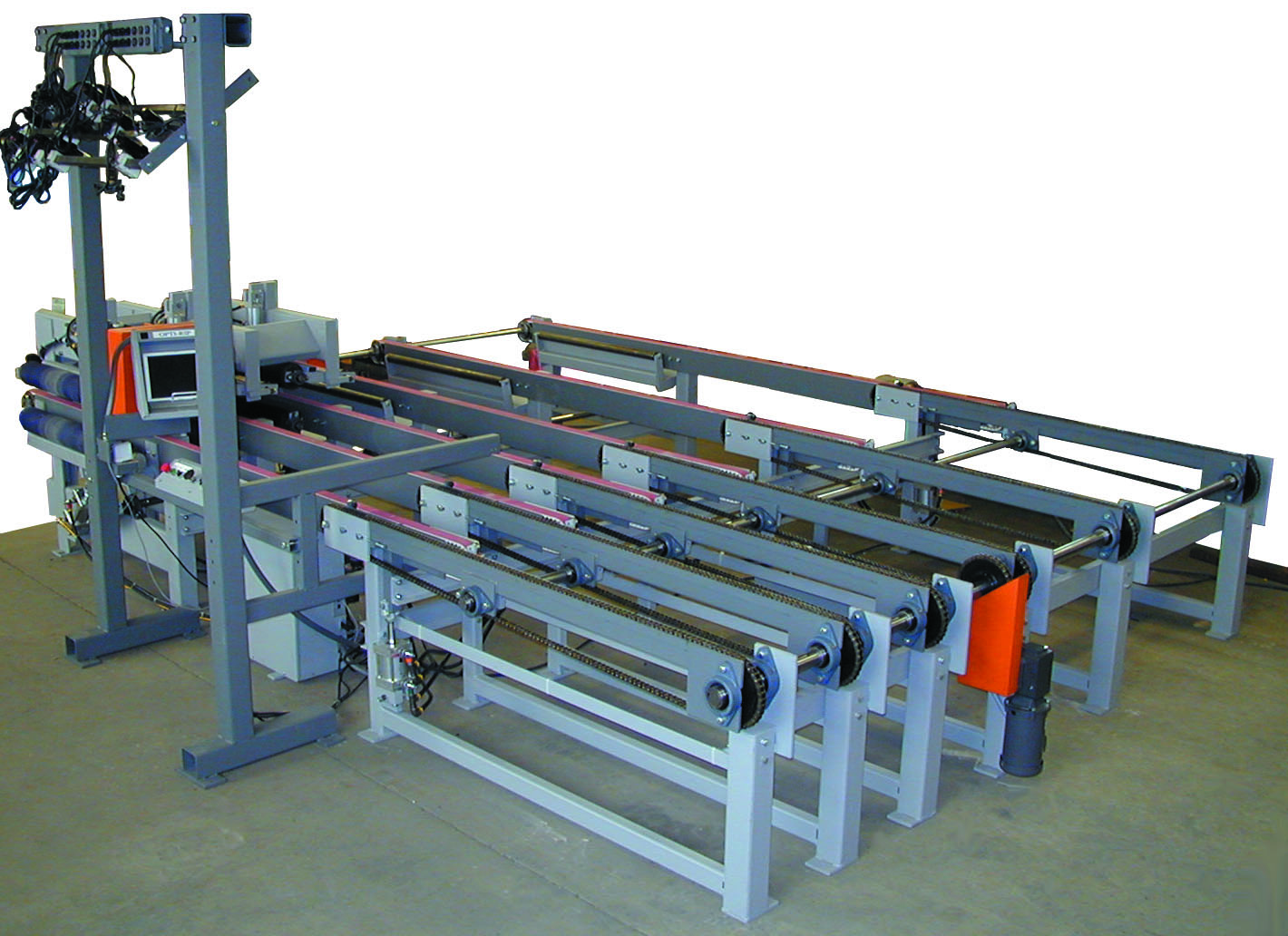

Vision and Scanning Systems

Cameron Automation has taken the technology step into the world of scanning in two distinct applications: 1). Top and bottom scanning on the Rip One Infeed and 2). Camera scanning for width and color on the Opti-Match. With over 20 years of optimizing and color matching experience, these machines are easy to run, maintain, and produce the way YOU want them to!

Click Below to learn more about Cameron’s Scanning Technology

Panel Layup and Color Matching

Taylor Manufacturing and Cameron Automation have developed the technology to save raw material and labor, while creating consistent sized and color matched panels at a high production rate. The Opti-Sizer will size panels accurately and convey them over a Taylor Glue Applicator, and the Opti-Match, which is a stand alone high production machine, will not only size the panel accurately, but also color match it as well.

Click Below to learn more about our Panel Sizing Machinery