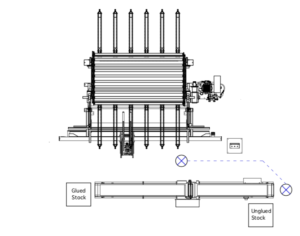

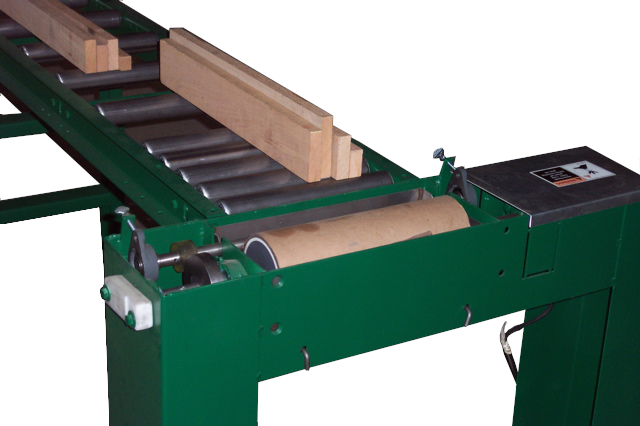

High Production Wood Clamping system; The Taylor Automated is the Industry’s Standard in Room Temperature Edge Gluing. This versatile carrier can handle many of the long, wide, and thick laminations that are needed in the industry.

Features:

- Produces up to 3500 ft2 / Shift

- Standard Machine Features

- Machine Frames Built to Match Product Dimensions

- Taylor’s Patented Clamp Design in Lengths to Meet your Needs

- PLC Controlled Automated Tightener / Flattener System

- Heavy Duty Motor Drive(s) for Rotation of the Sections

- Pneumatic and Hydraulic Models Available

As with all Taylor Clamp Carriers, smaller machines can be expanded as production requirements grow. Many customers will start with a (20) Section machine, and then expand that machine into a (40) Section or (60) section in the future, reusing approximately 90% or more of the existing components. Taylor’s goal is to grow with you through the years!!

(Additional Information and Specifications Below)