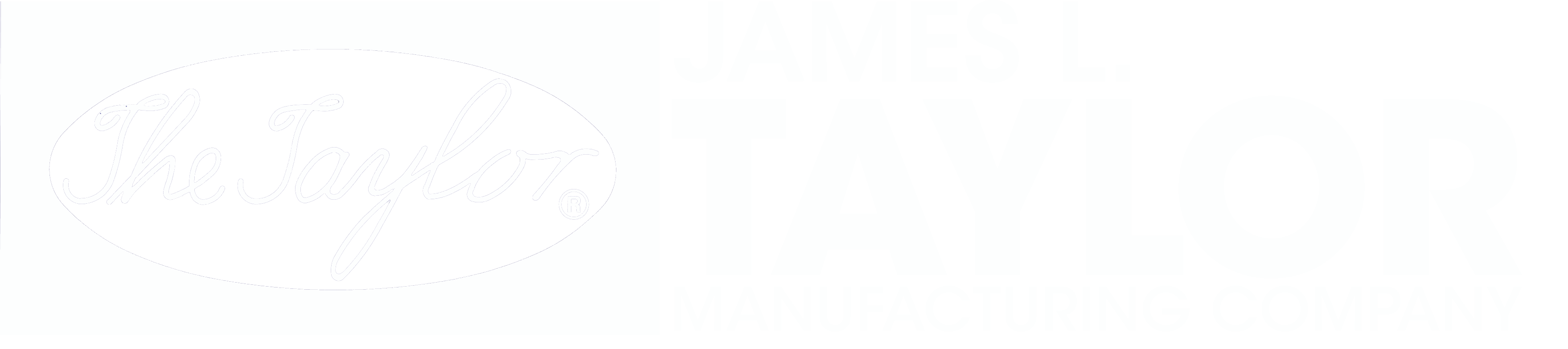

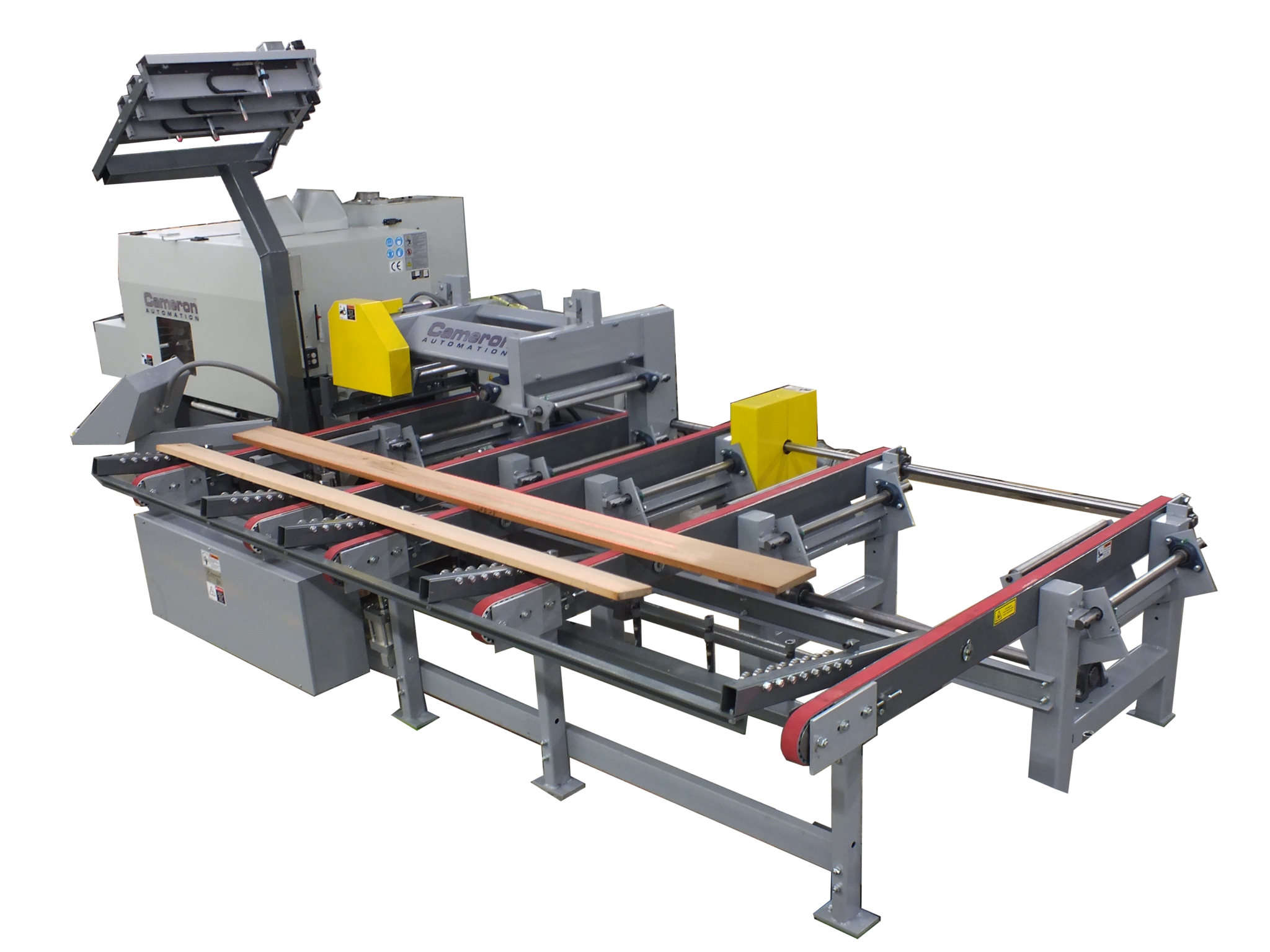

The Cameron Automation Rip-One is a complete lumber scanning, optimization, and gang ripping work cell designed for smaller shops. The Rip-One uses high resolution scanning technology to view both sides of a board to capture board dimensions and defects. The high resolution images are used to optimize each and every board going through the system. It also increases productivity dramatically by transforming gang ripping into a single person operation.

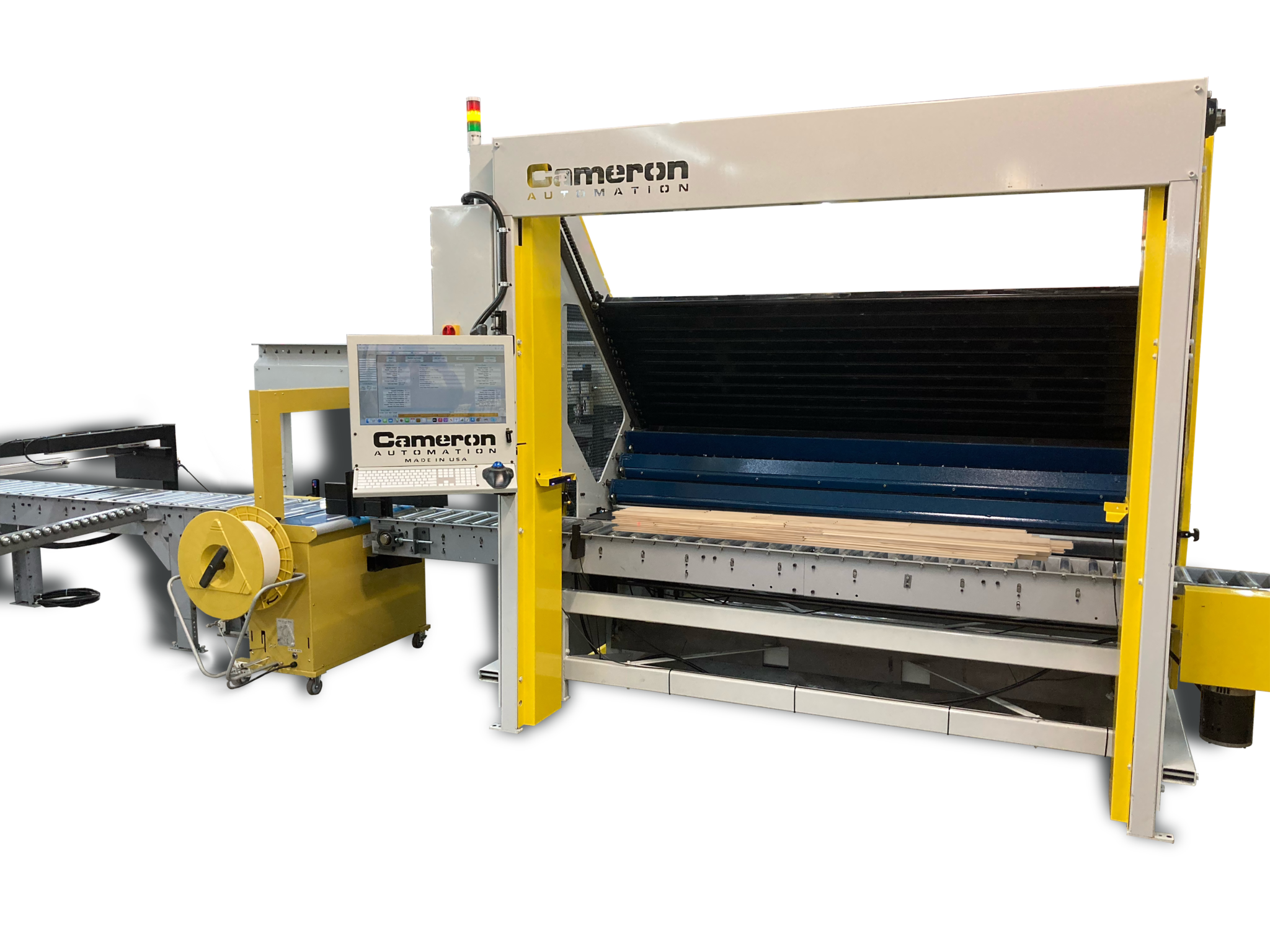

Cameron Saw Models

- #413A – 12″ Wide (2) Moving Blade, Multiple Fixed Blade Saw

- #413B – 18″ Wide (3) Moving Blade, Multiple Fixed Blade HD Rip Saw

- #413C – 24″ Wide (4) Moving Blade, Multiple Fixed Blade HD Rip Saw

List price for the entire system for ripping 12′ lumber, including a movable blade Rip Saw is tens of thousands or potentially hundreds of thousands of dollars less than other companies scanners alone. Optimization systems that don’t incorporate scanners typically read the width of the board in one or more places and at best work with only a two dimensional outer profile of the board. They are incapable of detecting wane or defects in the board. These optimizers can give a “best guess” ripping solution based on the board’s profile, but an operator is still required to finalize the solution based on the actual characteristics of the board. The Rip-One on the other hand brings the power of lumber scanning to the smaller shop, and until now, only larger shops could afford the advantages that could be gained by scanning lumber before ripping.