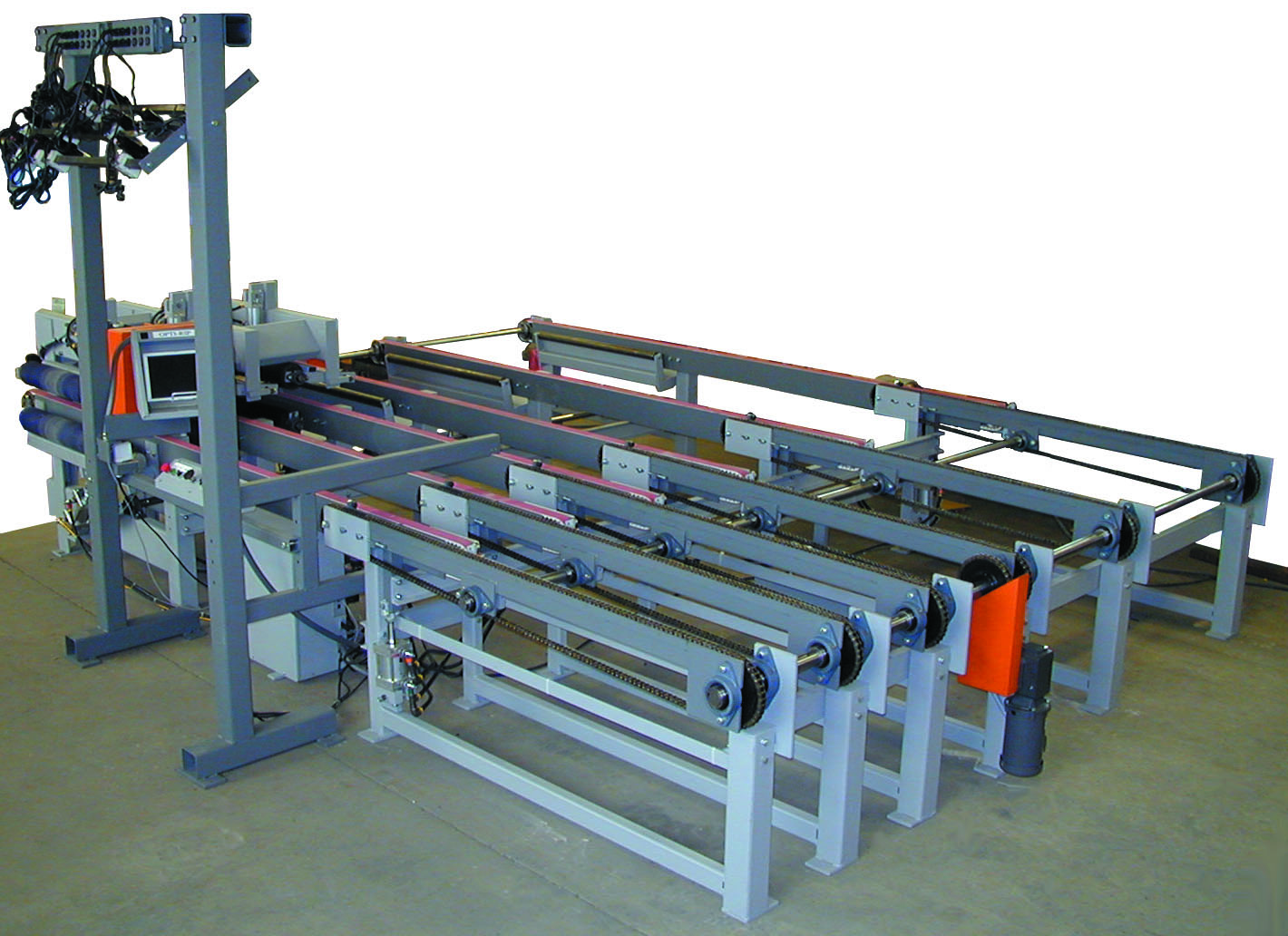

The Cameron Automation Flooring Nester

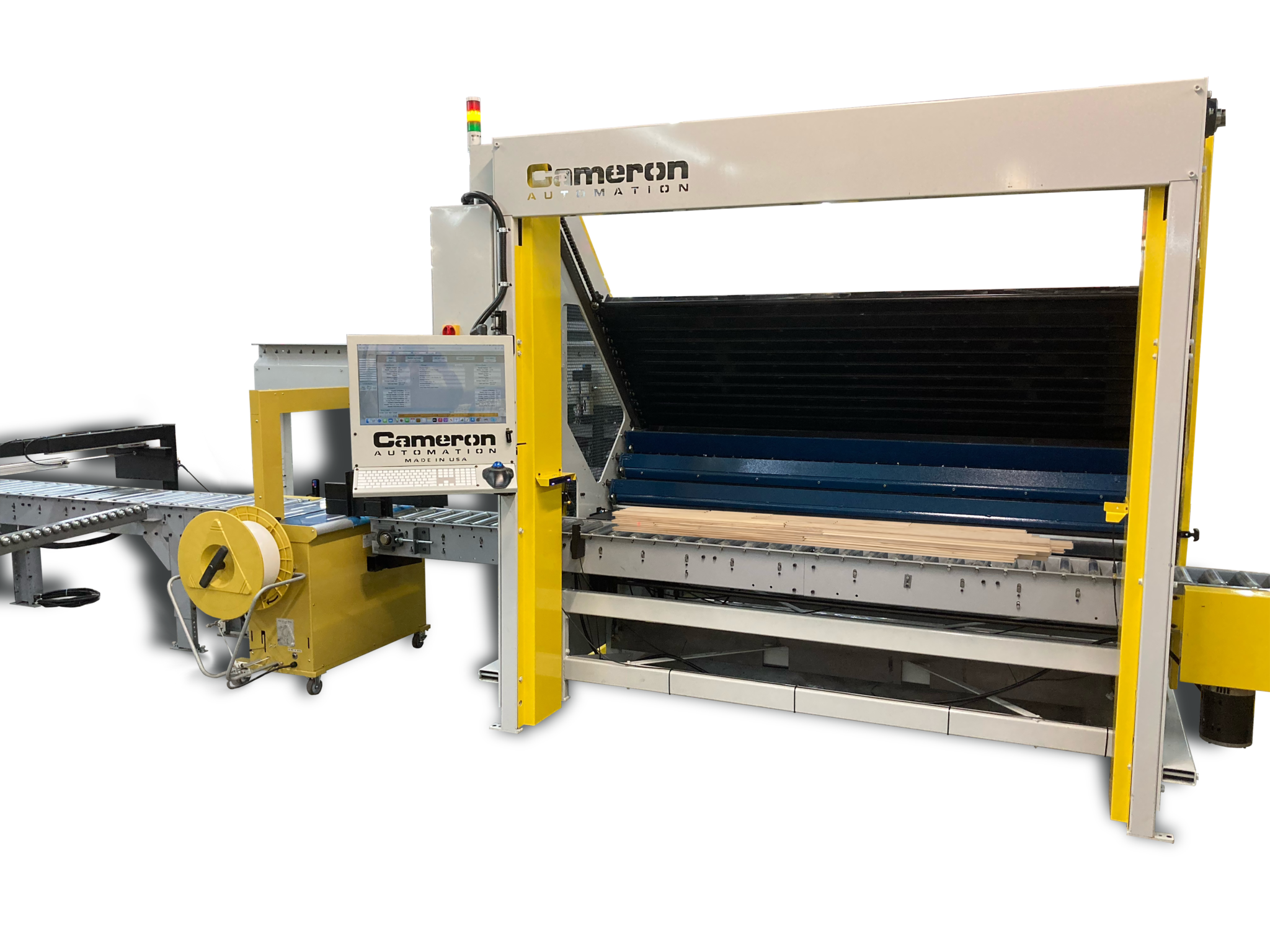

Stacking and packaging of nested bundles of Hardwood Flooring has always been a manual process. Cameron Automation has revolutionized this process with the Flooring Nester.

What Does the Machine Do?

The Cameron Flooring Nester creates accurate nested flooring bundles. Graders feed random lengths of material into one end of the machine, and the Flooring Nester releases a consistent, nested bundle of flooring out the opposite end. Most importantly, it creates bundles the exact square footage you want to sell, increasing your profits by up to 3%.

How Does it Work

The Cameron Flooring Nester is an elegant, efficient blend of hardware and software. The machine works by doing the following:

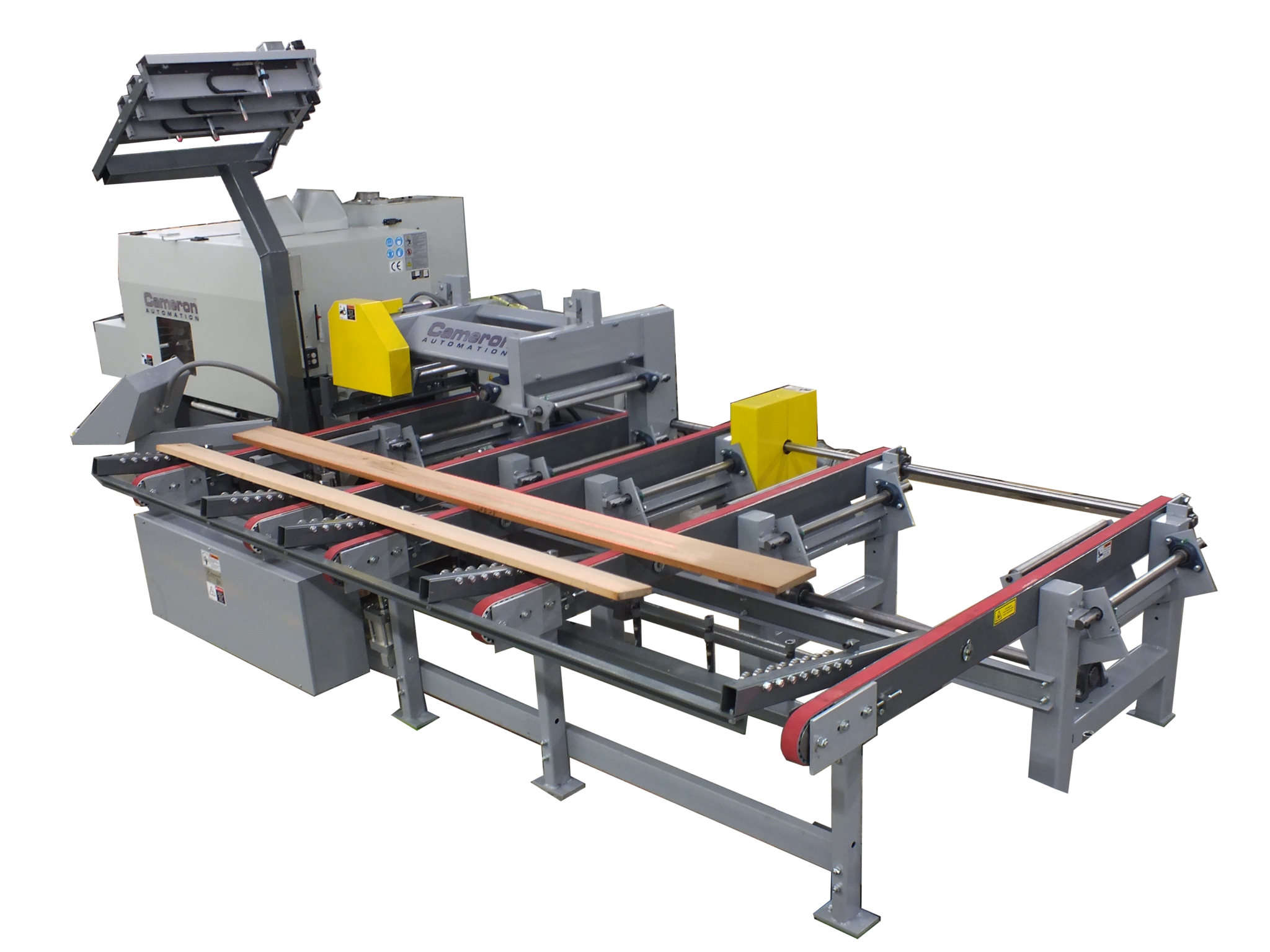

- Measuring strips of flooring, one by one, and feeding the information to the computer.

- Board information is relayed to the computer, which decides how to use each board.

- Sending boards which can be used now are sent to the out-feed to build a bundle, while others are stored in our unique scoop storage system.

- Strips of flooring the computer decides to use now are accumulated in the out-feed into rows. Rows are accumulated until a layer is made.

- Layers are stacked until a finished bundle is made. Finished bundles are pushed to a waiting conveyor, ready for strapping.

Combine Flooring Nesters on the same out-feed conveyor and strapping machine to increase productivity. This allows a single operator to manage multiple machines and keep your strapping and stacking operation centralized.

Information on the Out-feed Systems for the Nester can be found below

Contact us today to learn more about the Flooring Nester and how it can benefit your business!