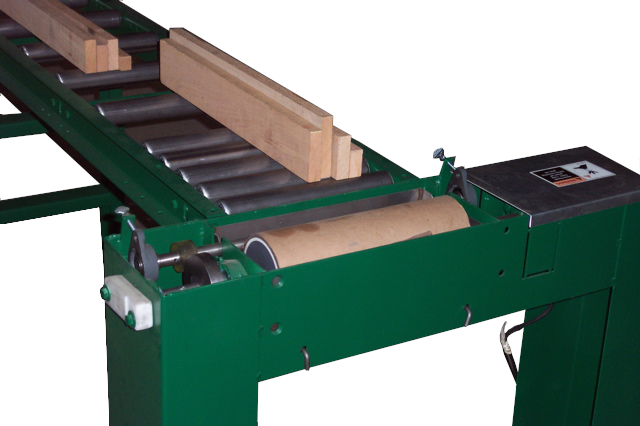

The Semi-Super Automated Clamp Carrier is the high production model of our most versatile line of clamp carriers. This machine has a Semi-Automatic Hydraulic Tightener(s) and Flattener System for the operator, and an Automatic Loosening System up above the work area.

Features:

- Produces up to 3000 ft2 / Shift

- Standard Machine Features

- Machine Frames Built to Match Product Dimensions

- Taylor’s Patented Clamp Design in Lengths to Meet your Needs

- Semi Automatic Clamp Tightener

- Pneumatic Panel Flattener

- Overhead Loosening System to Improve Cycle Time and Increase Production

- Heavy Duty Motor Drive(s) for Rotation of the Sections

- Pneumatic and Hydraulic Models Available

- (1) Operator and (2) Operator Setups Available

(Additional Information and Specifications Below)

As with all Taylor Clamp Carriers, smaller machines can be expanded as production requirements grow. The Classic Clamp Carrier is an ideal clamping system when a wide variety of products are to be glued.