Features:

- Standard Machine Models

- (5) Rotating Sections (Small to Medium Shops)

- (8) Rotating Sections (Medium to Large Shops)

- Section Capacities:

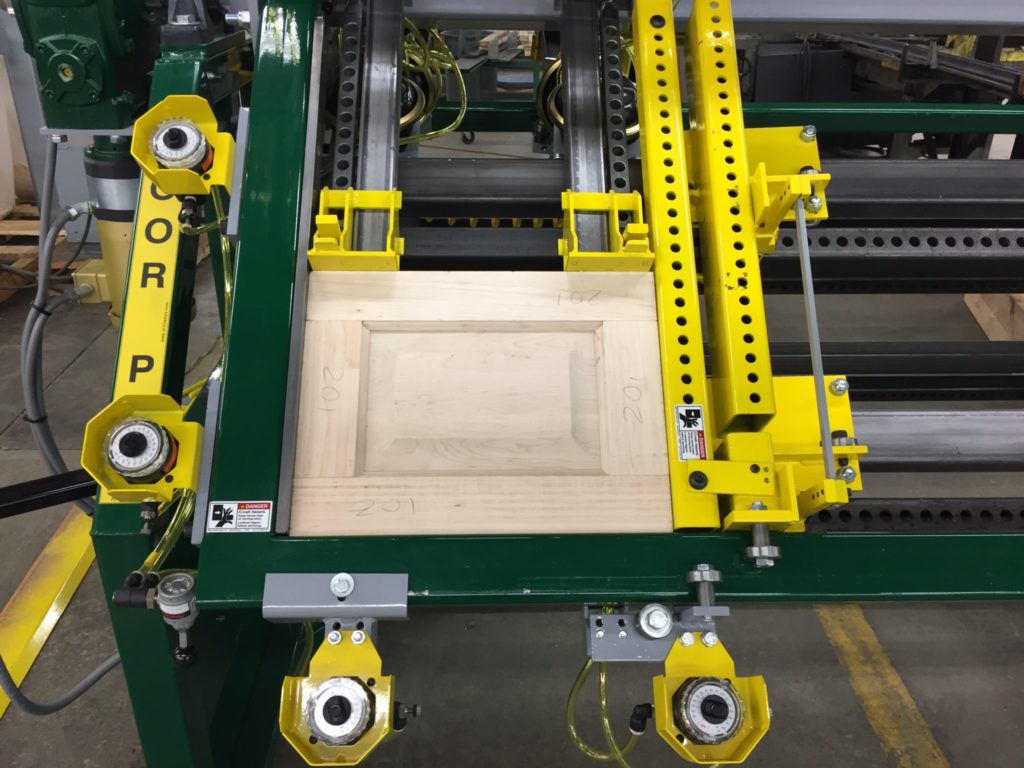

- Standard Machine = 26″ x 62″ Maximum Clamping Capacity

- Large Capacity Machine = 38″ x 96″ Maximum Clamping Capacity

- Innovative Dial Regulator System for Miter Doors

- Operators can Dial in Desired Clamping Pressure to Precisely and Accurately Square any Type of Miter Door

- Each Clamp can Dial Pressure IN or OUT to Make Fine Adjustments in Each and Every Corner

- Heavy Duty Diaphragm Cylinders Provide up to 1500 lbs of Clamping per Clamp

- Door Pro Frame is made of 100% Steel Construction

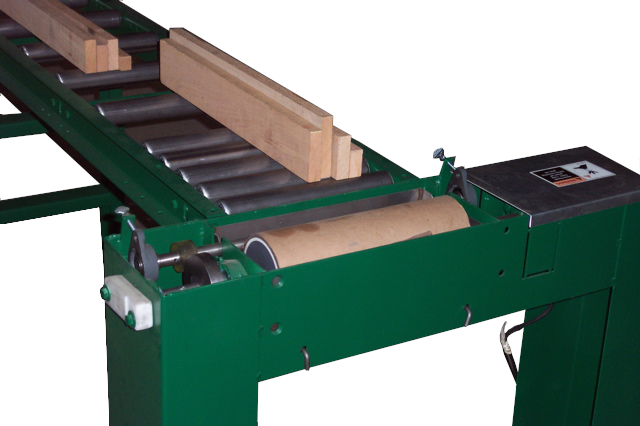

- Electric Gear Motor Provides Counter Clockwise Rotation for Operator Safety

- Single Button Control Box Activates Rotation and Includes Auto Index Feature

- Precisely Square and Clamp Stile & Rail Doors Too!!

- Includes a (1) Year Manufacturers Warranty

The Taylor Door Pro was a natural progression from the JLT Single Door Clamp. We have installed hundreds of machines in shops across North America. Machines come in (5) and (8) station models and some customers order an (8) station frame with (4) stations installed. This provides for easy expansion in the future.

(Additional Details and Info Below)