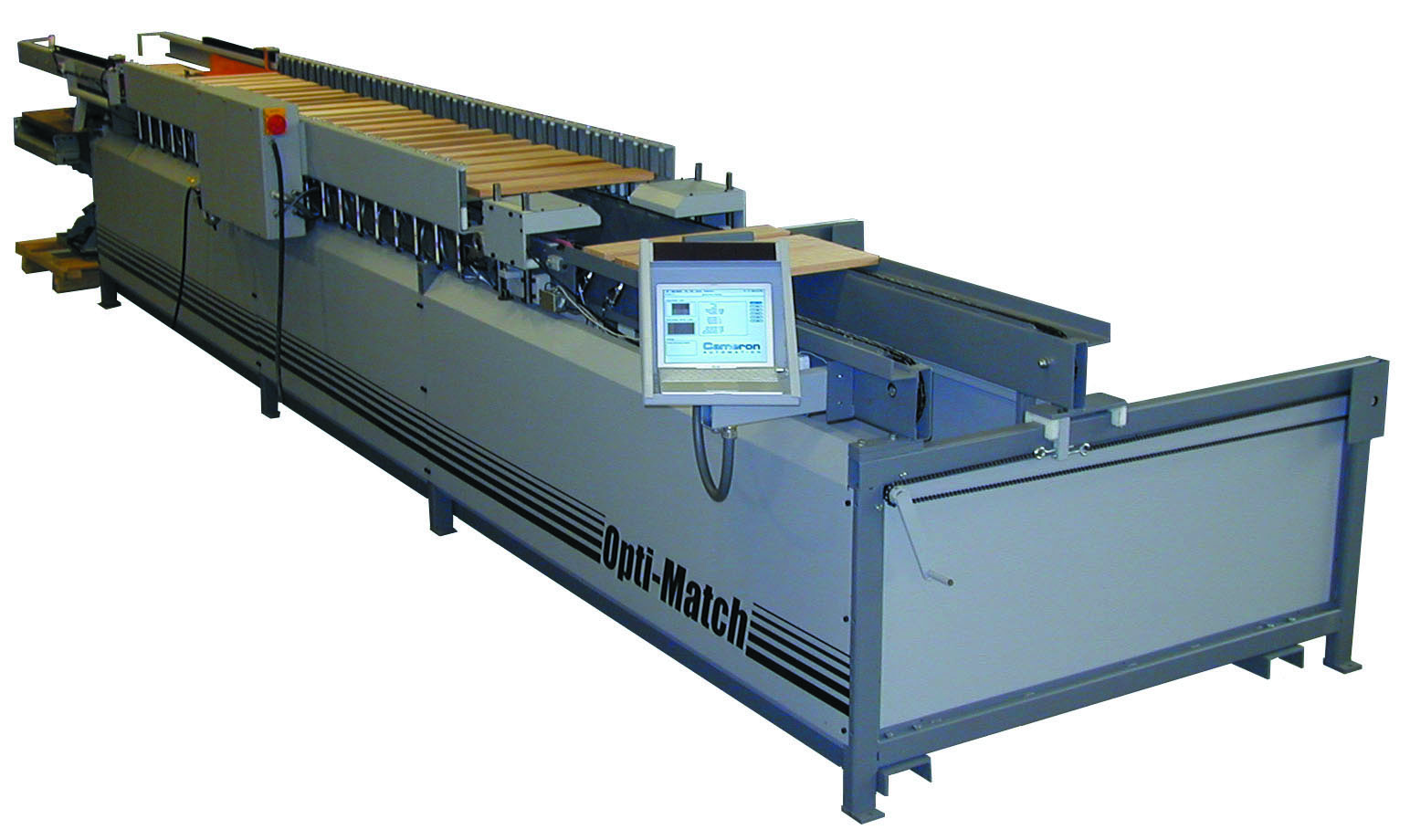

Opti-Match

The Opti-Match is the only machine to completely automate the color matching process for high quality solid wood panels

The Opti-Match is the only machine to completely automate the color matching process for high quality solid wood panels. The Opti-Match combines innovative scanning and sorting technology with complex computer programs to build and stack sized, color matched, and color blended panels, automatically. It completely eliminates the labor intensive and subjective job of manual color matching.

The Opti-Match Will:

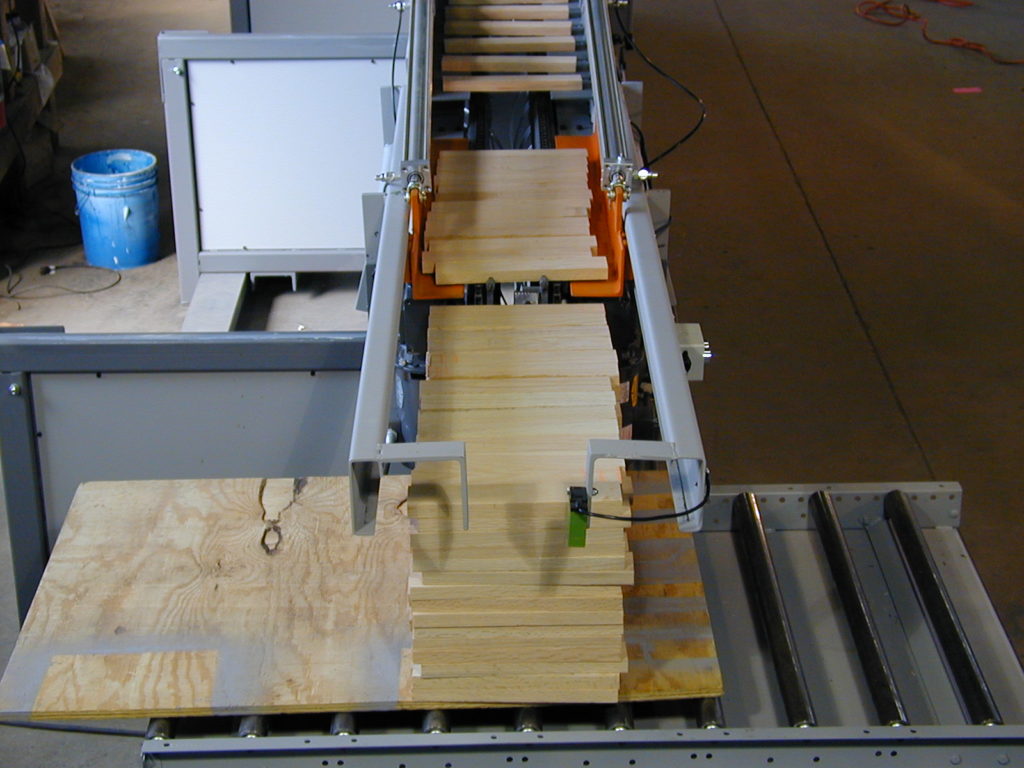

- Accurately measure board width and color from parallel ripped defected stock.

- Scan an area 5″ in from the end of each board as it traverses across grain.

- Choose from 22 boards at a time to find boards that are close in color to make a specified size panel.

- Assemble the chosen boards in the proper order to blend the boards in each panel.

- Automatically stack the assembled panels on a scissors lift, ready for gluing.

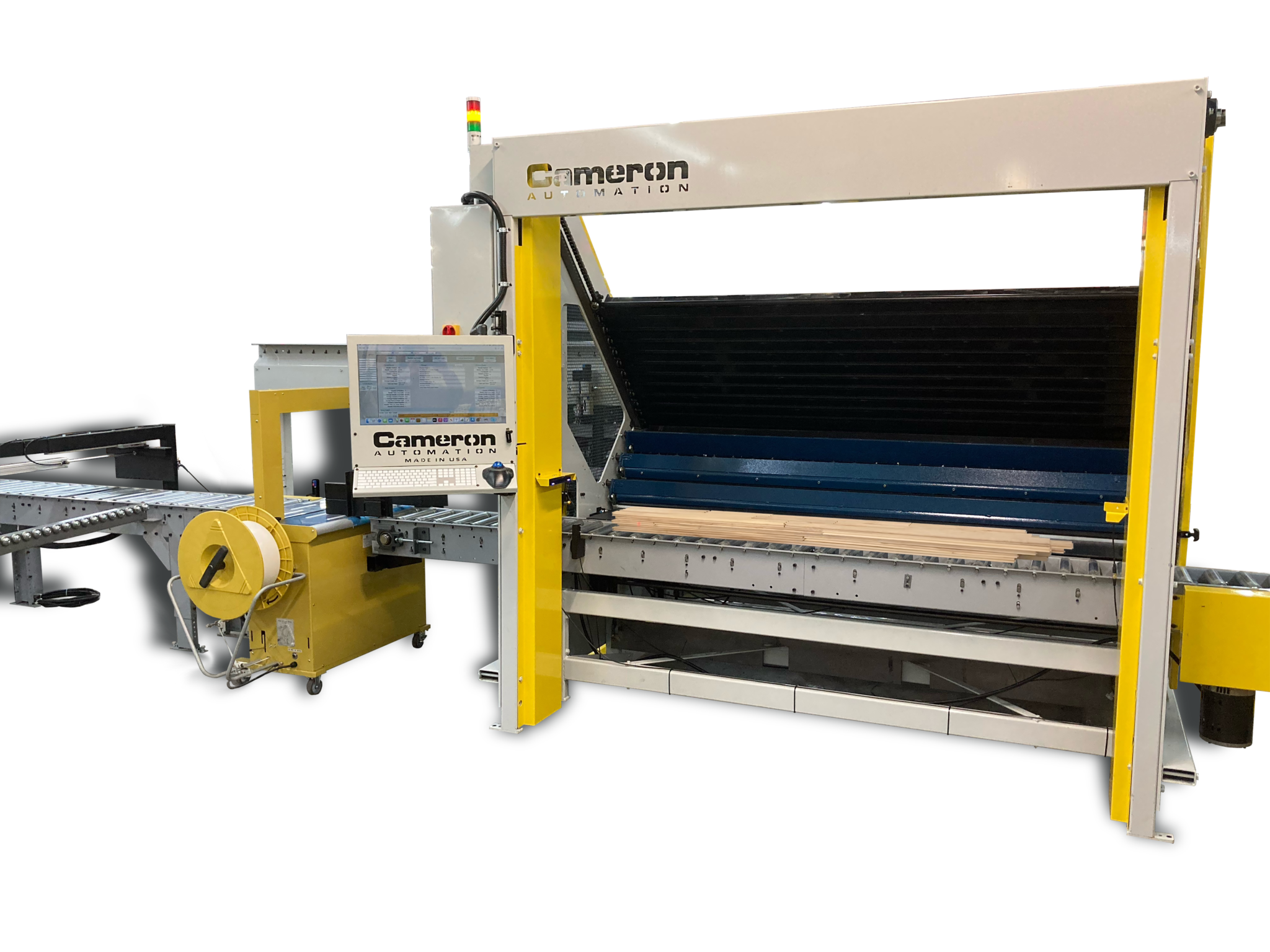

- Keep accurate tallies of panels and board pieces.

- Allow entering of multiple panel widths.

- Smart stack multiple panel widths.

With a production Level of approximately 1200 Panels per day (assuming 5 to 7 boards per panel), you can substitute the Opti-Match for 3+ men hand sizing panels.

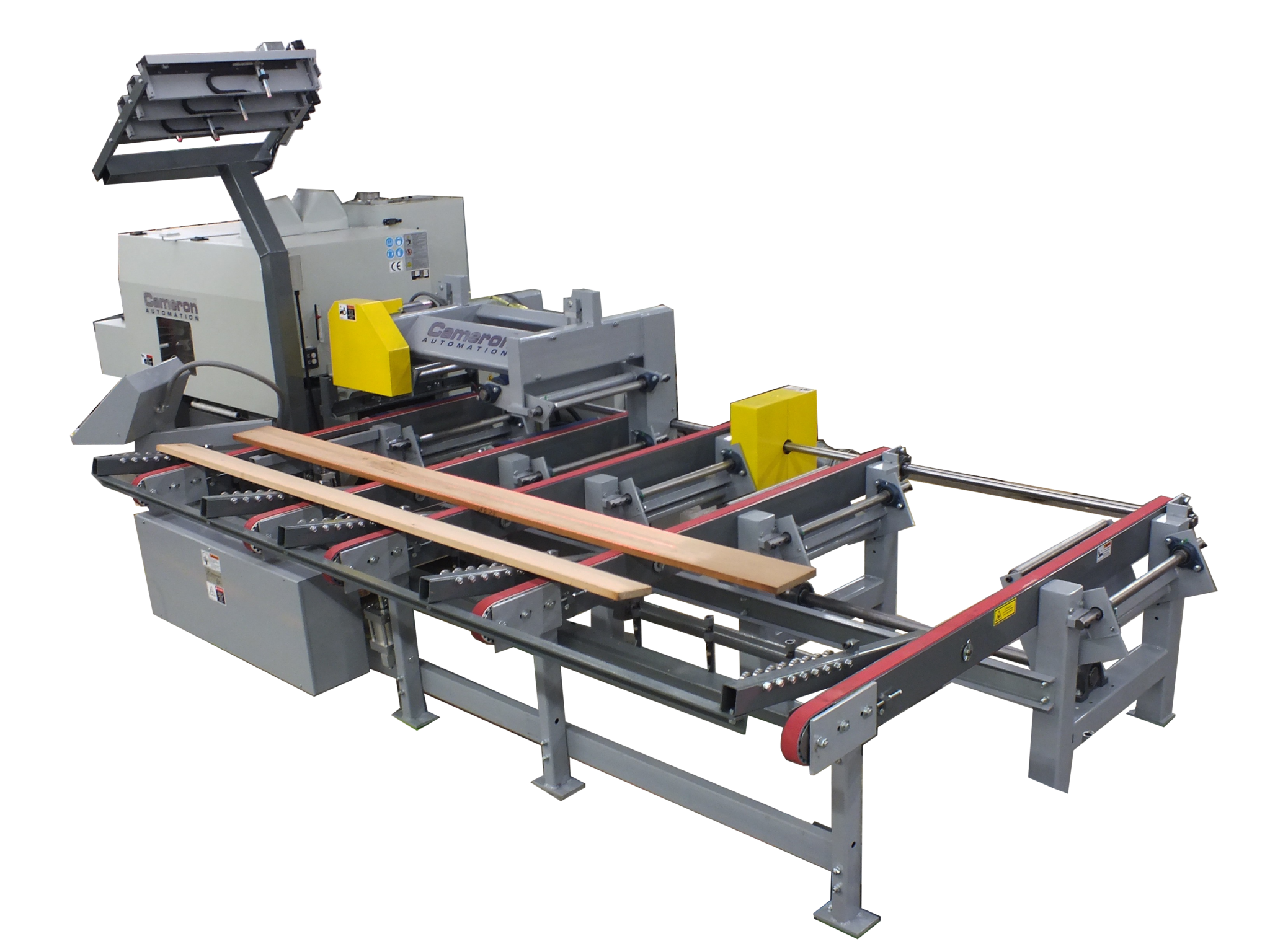

A Challengers Award Winner!

The Opti-Match was named a Challengers Award Winner at the IWF 2002 Show in Atlanta, Georgia.