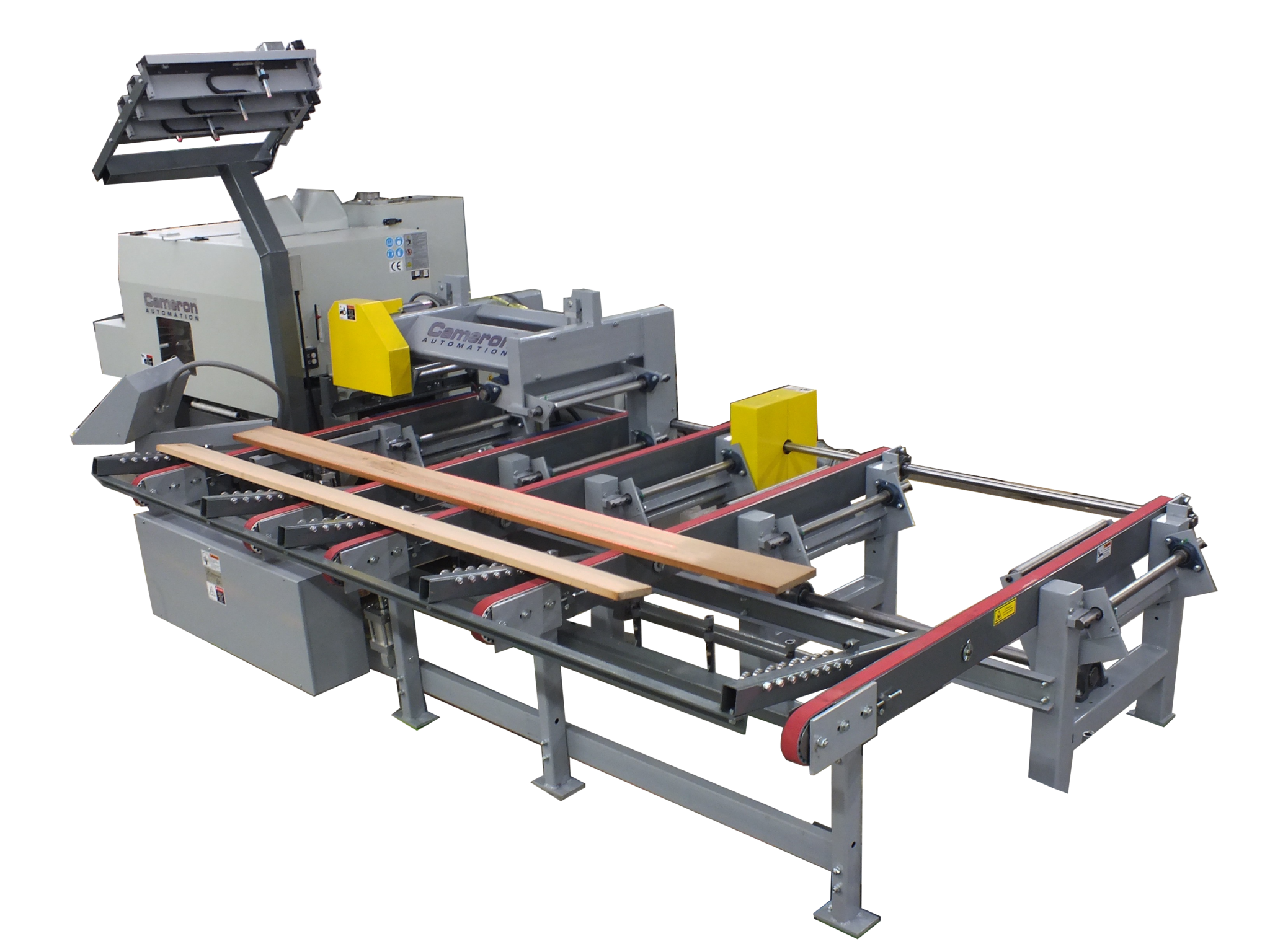

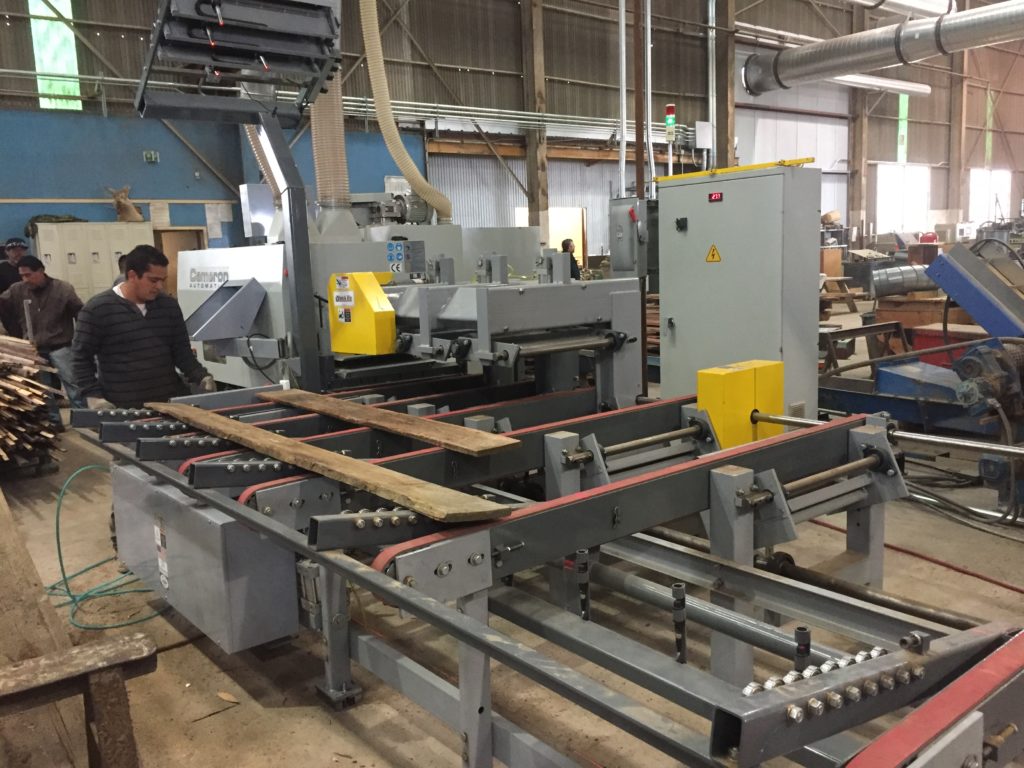

#415A- Quick Rip System

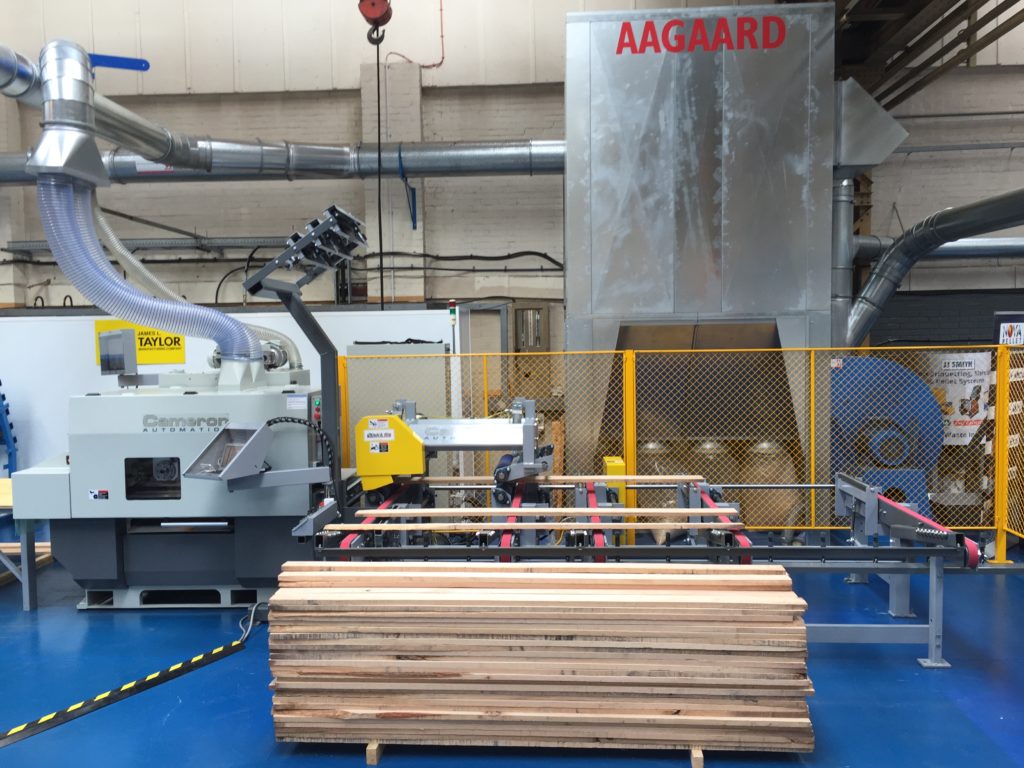

The Quick Rip System will cut up to (10) Boards per minute with the highest possible yield on the Market

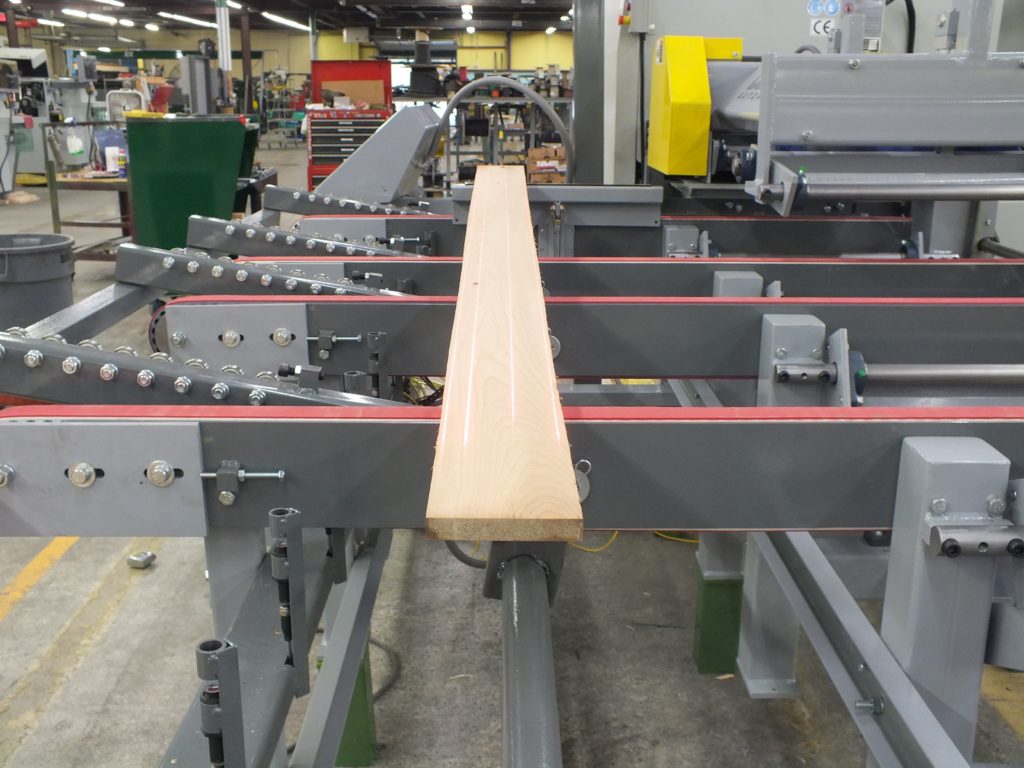

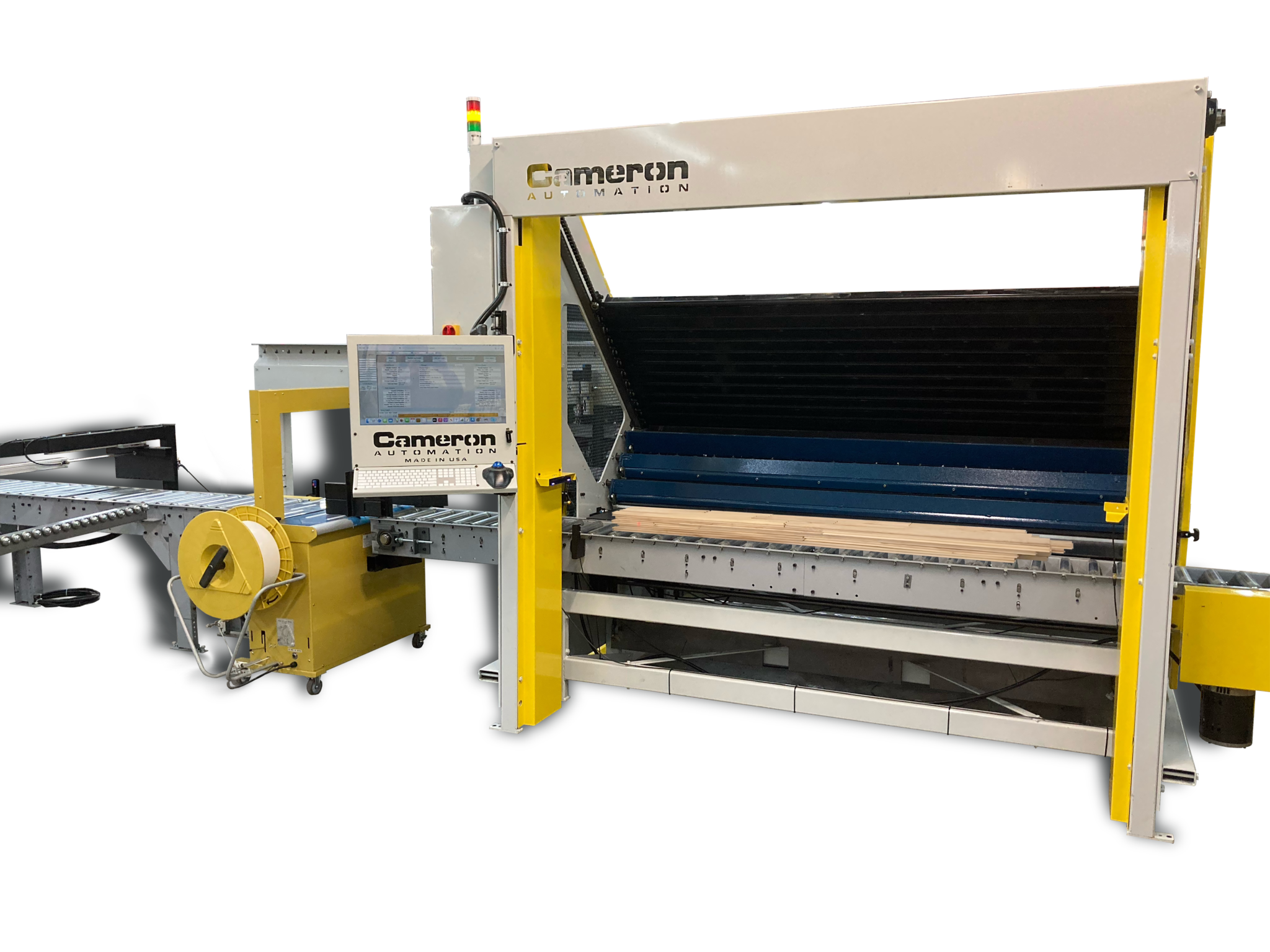

The Quick Rip System offers the highest yield in the market due to its fenceless design, powerful “Opti-Rip” optimizing software, and multiple moving blade technology in a few different model saws. Non straight boards are handled just as effectively as straight boards and the net result is lower raw material costs.

- Cameron Quick Rip Infeed with Fenceless, Servo-Driven Board Positioner with Extremely High Accuracy

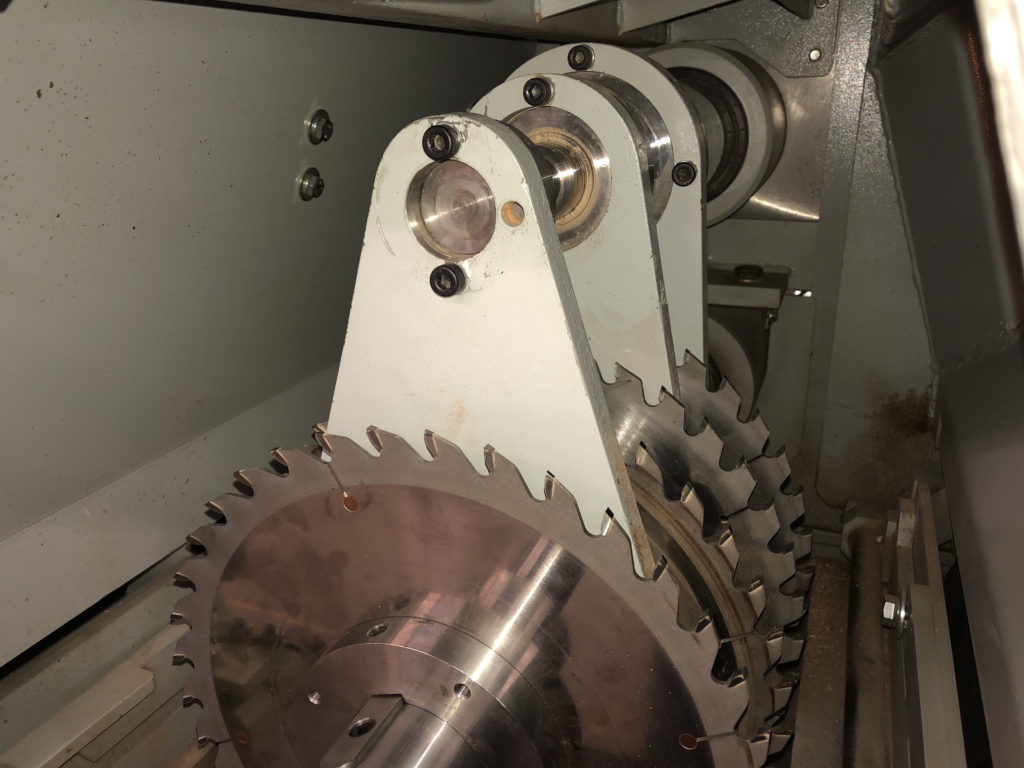

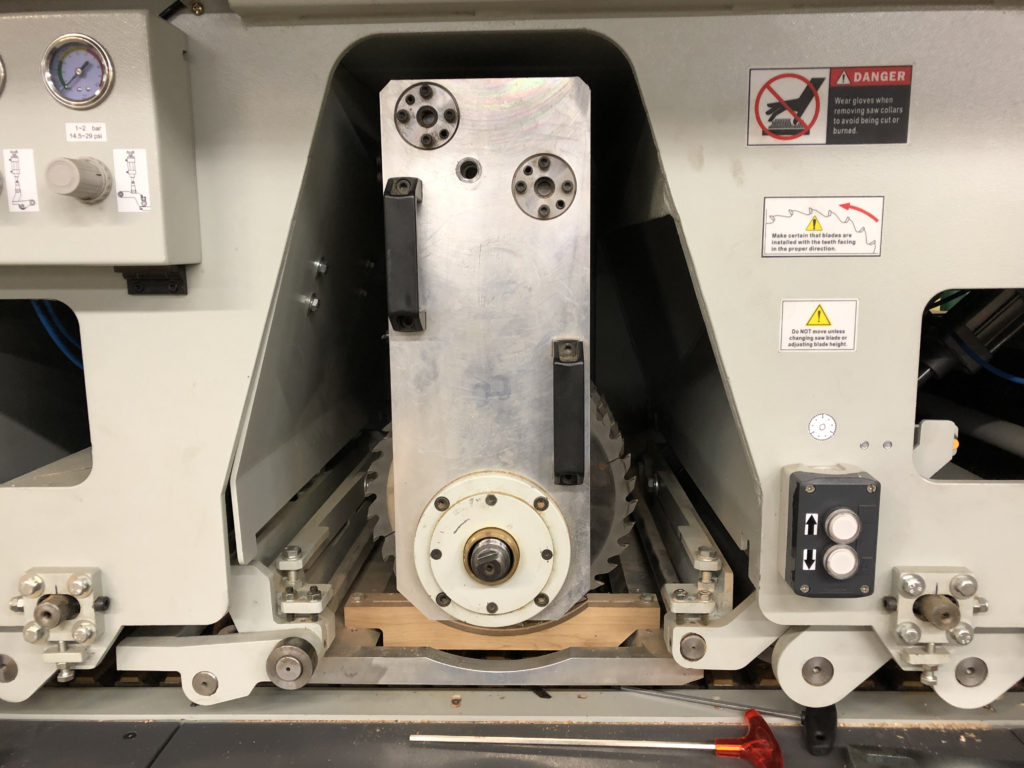

- Multiple Moving Blade, Multiple Fixed Blade Setups

- Completely Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

- Highest Board Yield on the Market!!!

Cameron Saw Models:

- #413A – 12″ Wide (2) Moving Blade, Multiple Fixed Blade Saw

- #413B – 18″ Wide (3) Moving Blade, Multiple Fixed Blade HD Rip Saw

- #413C – 24″ Wide (4) Moving Blade, Multiple Fixed Blade HD Rip Saw