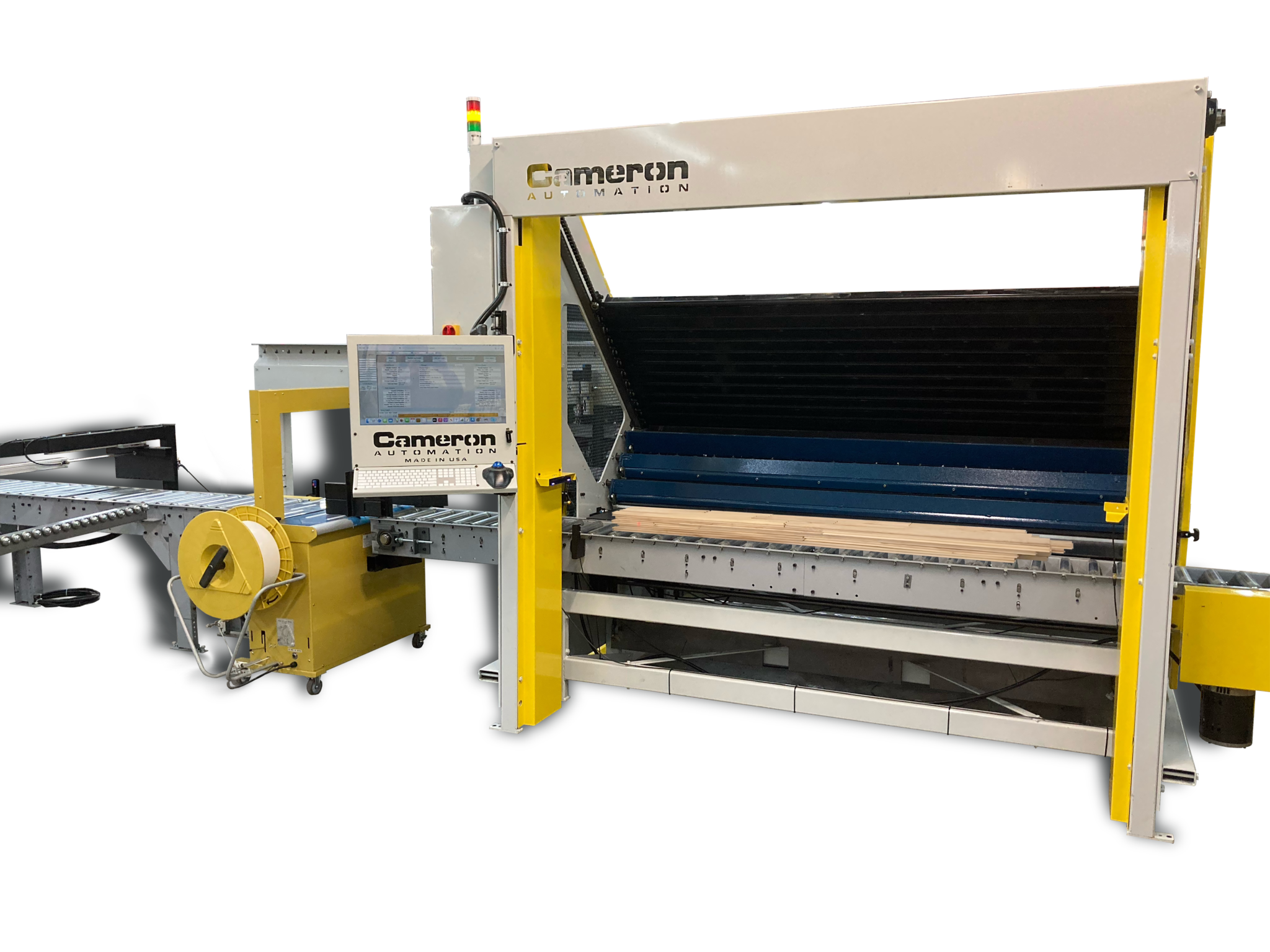

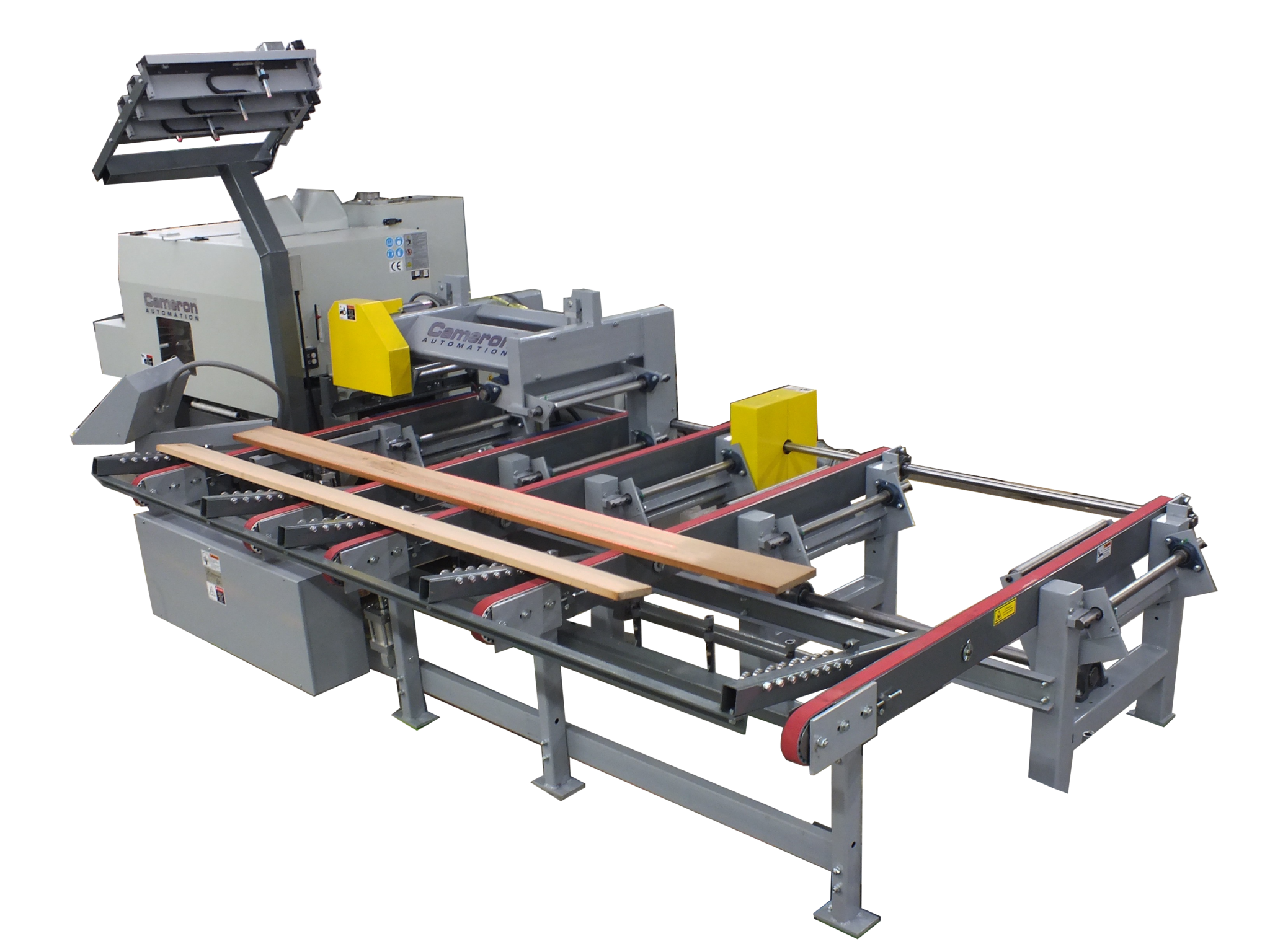

#611A- Quick Chop Plus

High Speed, Push Feed, Optimizing Chop System designed for the Rip First AND Chop First Factories

Redesigned from the ground up in 2018, the Quick Chop Plus is a complete and affordable push feed chop saw optimization system. Based off of the time tested #37A- Quick Chop Design and the Powerful “Quick Chop” software platform, The Quick Chop Plus offers many of the same features at more than double the production. The Quick Chop Plus can cut around 30 lineal ft. of material a minute. This totals 13,000+ Lineal Feet per (8) Hour shift.

Like our other Cameron Platforms, the Cameron “Quick Chop” Program is robust and powerful. The Quick Chop’s software runs on a full featured computer – not just a keypad and a PLC. Because the Quick Chop is designed with the custom shop in mind, the software is sophisticated yet easy to use and easy to understand.

The Quick Chop Will:

- Accurately cut boards to length from cut lists plus or minus .030″. For even closer tolerances the Quick Chop chop saw optimization system offers the option of a lineal encoder for accuracy of +/- .010″.

- Allow operator to use familiar crayon based defect marking and grading.

- Increase yield of cut stock and prioritize chop lengths.

- Make accurate and smooth cuts with a mechanical chop saw.

- Keep accurate tallies of production and yield.

- Increase operator safety.

- Network with office computers to import cut lists from spread sheets and review reports.

- Print lengths and references on parts with an optional inkjet printer.

- Wirelessly network with other Quick Chops and the Quick Rip to collectively work on jobs and increase yield.