-

Clamp and Square 100+ Stile and Rail Cabinet Doors Per ShiftNext

Clamp and Square 100+ Stile and Rail Cabinet Doors Per ShiftNext -

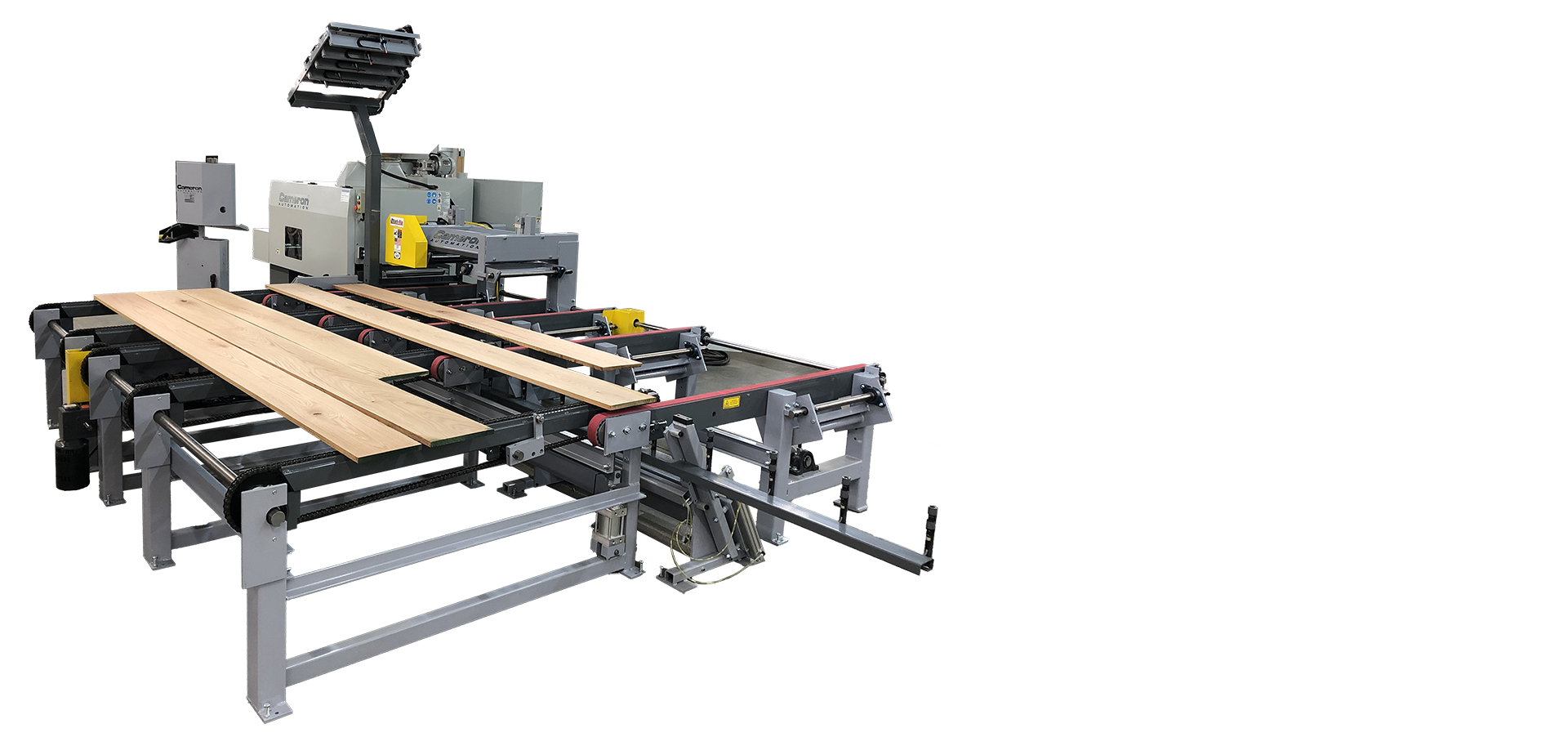

Lumber optimization technology engineered, manufactured, and serviced from our 100,000 sq. ft. facility in Poughkeepsie, NYNext

Lumber optimization technology engineered, manufactured, and serviced from our 100,000 sq. ft. facility in Poughkeepsie, NYNext -

High tech machinery for automating and improving common rough mill processesNext

High tech machinery for automating and improving common rough mill processesNext -

High tech machinery for automating and improving common rough mill processesNext

High tech machinery for automating and improving common rough mill processesNext

-

JLT CLAMPS

Explore brand -

TAYLOR

Explore brand -

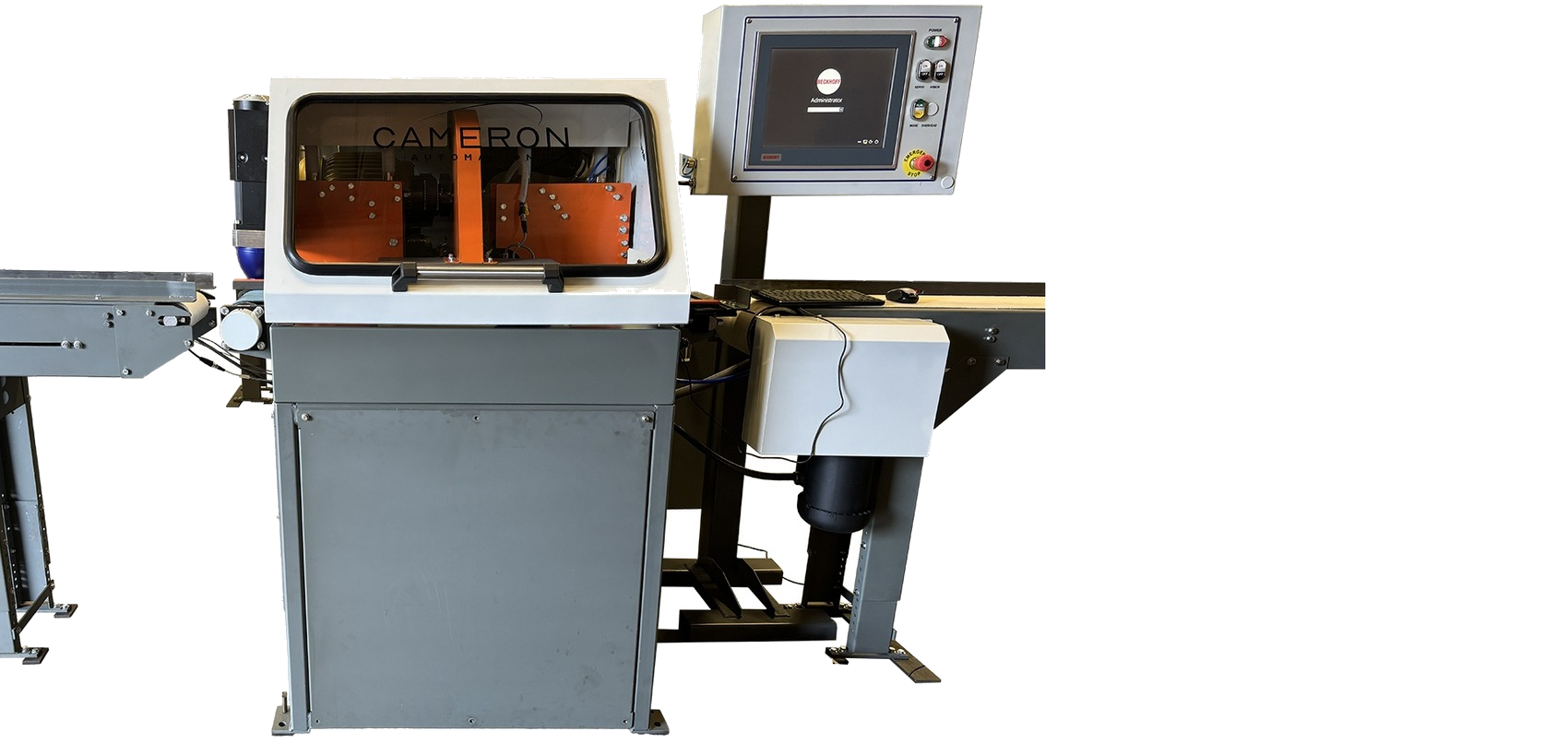

CAMERON

Explore brand -

ULTIMIZERS

Explore brand