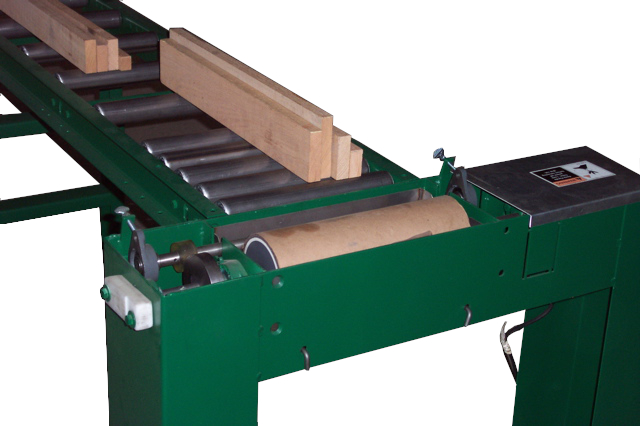

#30J- Conveyorized Glue Applicator

The Taylor Conveyorized Glue Applicator is designed for use with PVA type adhesives. It is equipped with a stainless steel glue pan, doctor roll, and outfeed cross bars.

Features:

- Customizable Machine Design that fits your Gluing Area and Products

- Infeed and Outfeed Lengths are variable and can be built to suit your needs. Typically the outfeed length is built to match the width of the Clamp Carrier

- 13″ Wide, 26″ Wide, and 39″ Wide Glue Roll Models are available to fit your production needs

- Stainless Steel Live doctor roll for precise and adjustable glue spread

- The Doctor Roll spins in the opposite direction of the Glue Roll which provides a controllable spread

- Overnight glue storage system

- Stainless Steel Glue Pan and Stainless Steel Cover

- Felt Covered Removable glue roll

The Taylor Conveyorized Glue Applicator is an automated glue application and stock handling system. The system applies adhesive to the wood stock before clamping.

The machine is designed with components which stand up to the rigors of a high production gluing operation. In addition, an adjustable safety clutch protects the conveyor chain against damage when careless operation results in wood jamming in the conveyor. This feature reduces down time and is self-healing so the machine returns to normal function once the jammed stock is removed.